Simulated moving bed (SMB) chromatography sets the benchmark for productivity in the continuous processing of chromatographic separations. This has proven useful in various cost-critical applications, from fine chemicals engineering to pharmaceutical production. The success of high throughput SMB systems hinges on their ability to isolate a single chemical compound or class of compounds from large quantities of bulk material. In chemical and pharmaceutical contexts, this represents a unique opportunity to finely control the purity and quality of active ingredients (AIs).

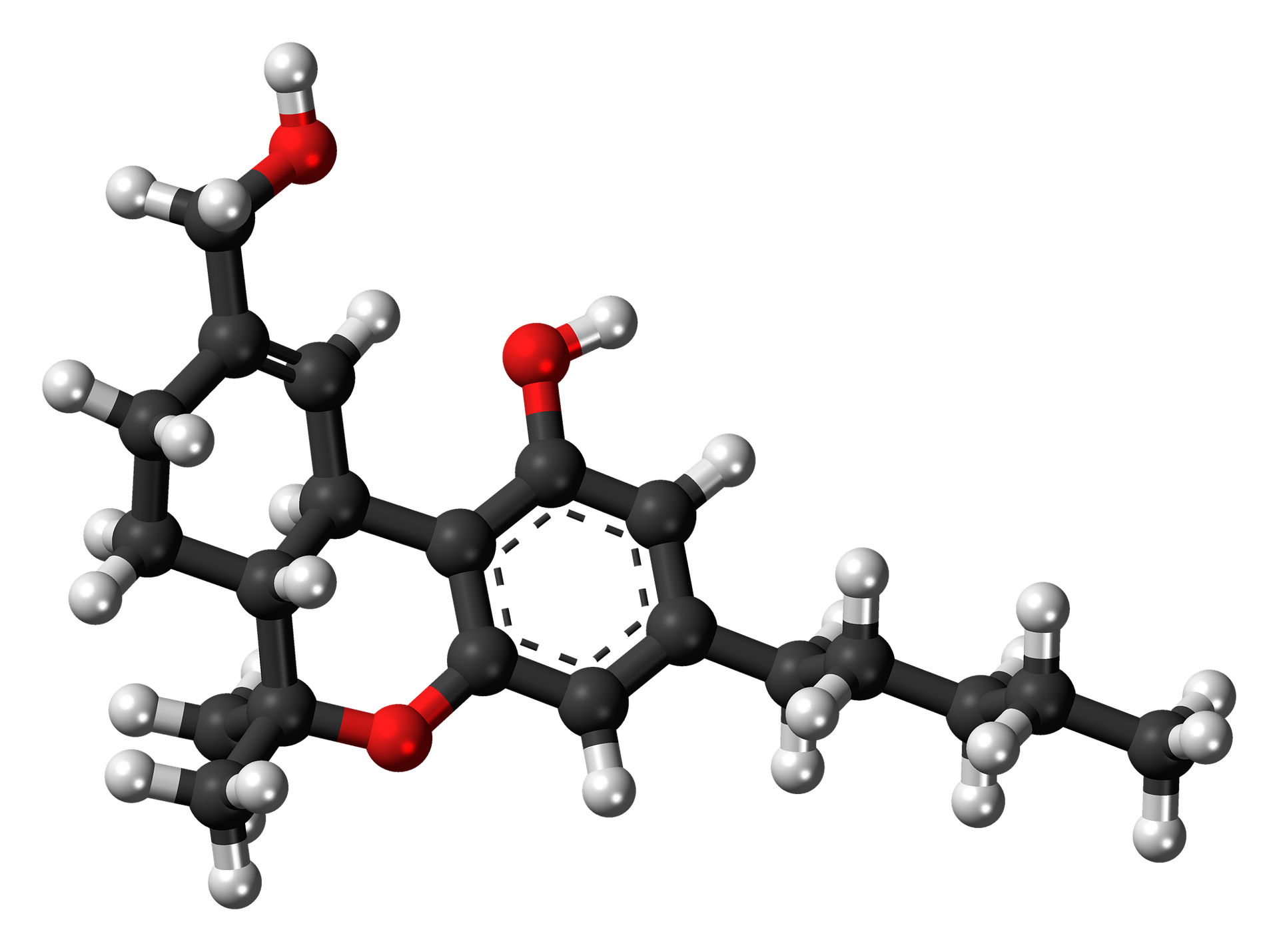

Purifying chemical compounds or classes at the percent by mass range is also a key challenge in the cannabis and hemp industry. The gradual relaxation of cannabis prohibition has fuelled a booming global market that relies on both strict quality control and rapid workflows. These conflicting KPIs require a robust system for isolating specific cannabinoids from as many 100+ distinct compounds present in the raw plant material. SMB systems have been explored as a potential solution to this problem.

Outlining SMB Systems

Highly engineered for large scale separations, SMB systems typically use four or more columns which are plumbed together – and to the mobile phase pump – via a set of valves. This modular series of components forms one continuous ring, converting single-column batch separation into a high throughput continuous process.

SMB systems can subsequently be used to rapidly enrich – or deplete – cannabinoids like tetrahydrocannabinol (THC) from cannabis leaves and dried hemp, using a single modular instrument. This is carried out by combining the cannabis plant with a solvent to generate a crude extract, which is pumped into the SMB system. The solid phase movement is simulated by simultaneously switching the valve positions on the continuous system, causing an increase in dilution efficiency and absorbent utilization. Using this technique, cannabinoids can be easily isolated from bulk streams in the percent by mass range, yielding high purity extracts in a faster and more cost-effective manner than ever before.

Another benefit of SMB systems in industrial processing of cannabinoids is the technology’s applicability for both natural and synthetic goods. A range of raw material types can be separated with greater productivity and significant cost-reduction in terms of consumed solvents and solid-phase media.

SMB Systems from Knauer

Knauer offers class-leading SMB systems under the AZURA® range; a new industry standard for rapid separation of cannabinoids from cannabis and hemp. This SMB system comprises four pumps and seven distinct multi-position valves, for the utmost flexibility in large scale chromatographic separations. We offer two different scales of the AZURA® SMB system:

If you would like any more information about using AZURA® SMB systems for large scale cannabinoids extraction, simply contact a member of the Knauer team today.

"Currently, the SMB is the only purification process that can be duplicated on a large scale for the purification of cannabinoids."

Christian Ulbricht, Chromatography Specialist

The SMB System for cannabinoid production is optimized for the separation of binary mixtures in gram to kilogram-scale. Its special emphasis is put on the continuous operation mode and high productivity and purity.

We implement individual requirements in applications for our customers from various industries. Based on existing systems such as the SMB Pilot System or with the help of high-performance frameworks, we create and develop individual systems for special requirements that are highly scalable and flexible.

Our extensive expertise and high technical know-how allow us to achieve highly efficient development, and measurable cost savings for our clients.

Disclaimer:

KNAUER does not endorse the use of its products in connection with the illegal use, cultivation or trade of cannabis products. KNAUER does not endorse the illicit use of marijuana, we merely provide an overview of the methods and systems of cannabis analysis.