AZURA® SMB Lab Systems

The AZURA® SMB Lab Systems are optimized for the multicolumn separation of binary mixtures of small molecules in gram-scale.

AZURA® SMB Pilot Systems

To extract high-purity pharmaceutical active ingredients from natural products at high yields is a major challenge.

Simulated moving bed (SMB) chromatography saves time and money in the lab

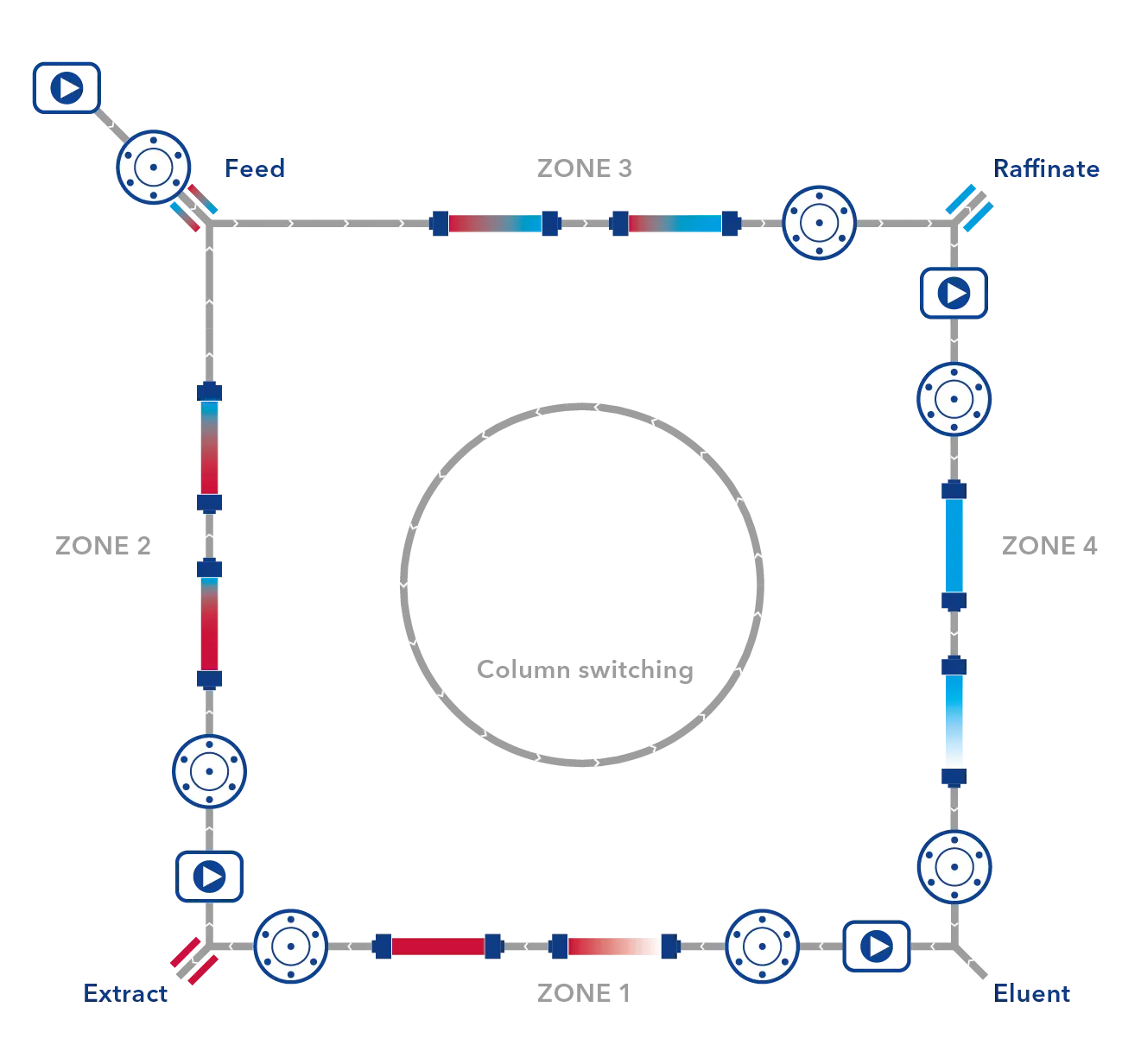

Simulated moving bed chromatography (SMBC) is increasingly applied as a separation technique in the pharmaceutical industry, production of fine chemicals, and in the field of bioengineering.

SMB is a multi-column method in process chromatography that enables substance mixtures to be continuously separated and extracted in two fractions. Its efficiency is significantly higher than batch chromatography, through better utilization of the column stationary phase.

Although in principle limited to two fraction separations, each partial fraction can be separated into further fractions by repeated use of the SMB process – down to binary substance mixtures.

Typically, the SMB process is used for two component mixtures, like chiral separations or mixtures with a "leading" or a "trailing" key product peak in the chromatogram.