-

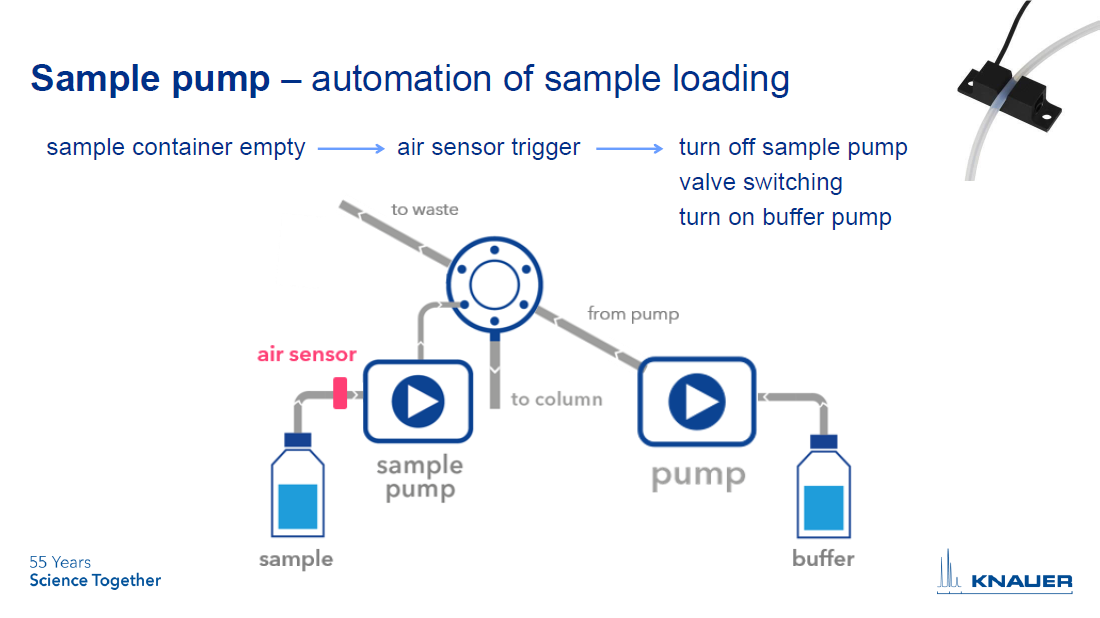

Figure 1: Using a sample pump for automation

-

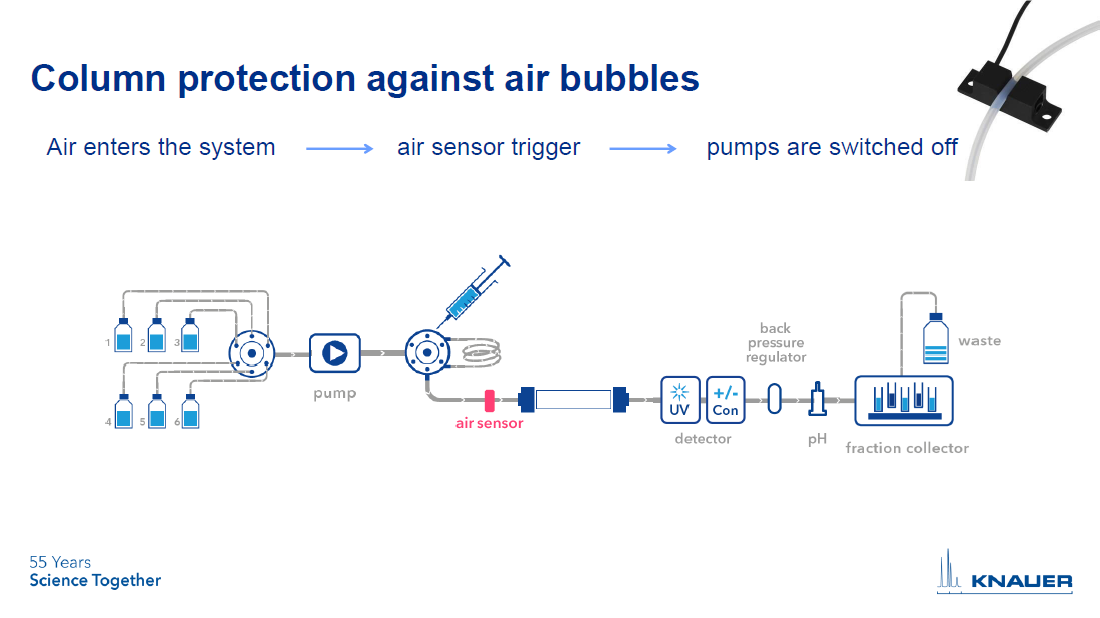

Figure 2: Using an air sensor for protecting the FPLC column

The first possibility for using an air sensor is the automation of sample injection to the column using a sample pump. Install the air sensor directly on the inlet tubing at the sample pump. Once the sample container is empty air in the tubing will be detected. This will trigger a response in the software, which can be programmed. In most cases the sample pump will stop pumping the injection valve will switch to the system pump, which will start pumping (see Figure 1).

The second possibility for using an air sensor is protecting the column against introduction of air. Placing an air sensor directly in front of the column allows you to tell the software to automatically turn off the system pump if air is detected (see Figure 2).