High-Pressure Dosing Pumps

Precise dosing in the laboratory and in production

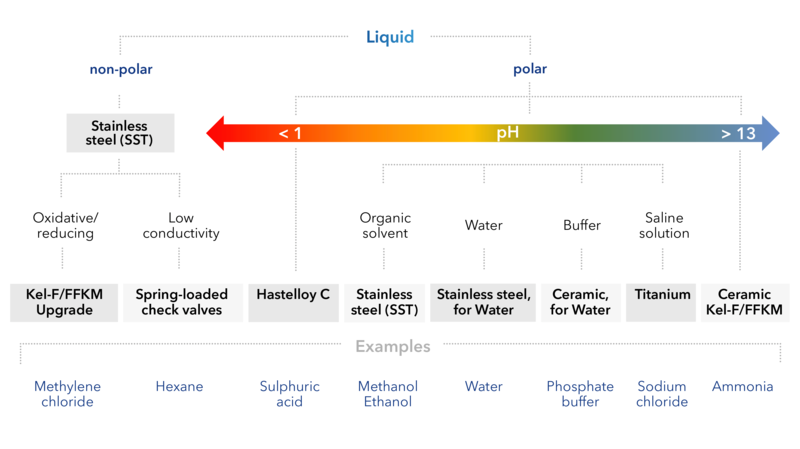

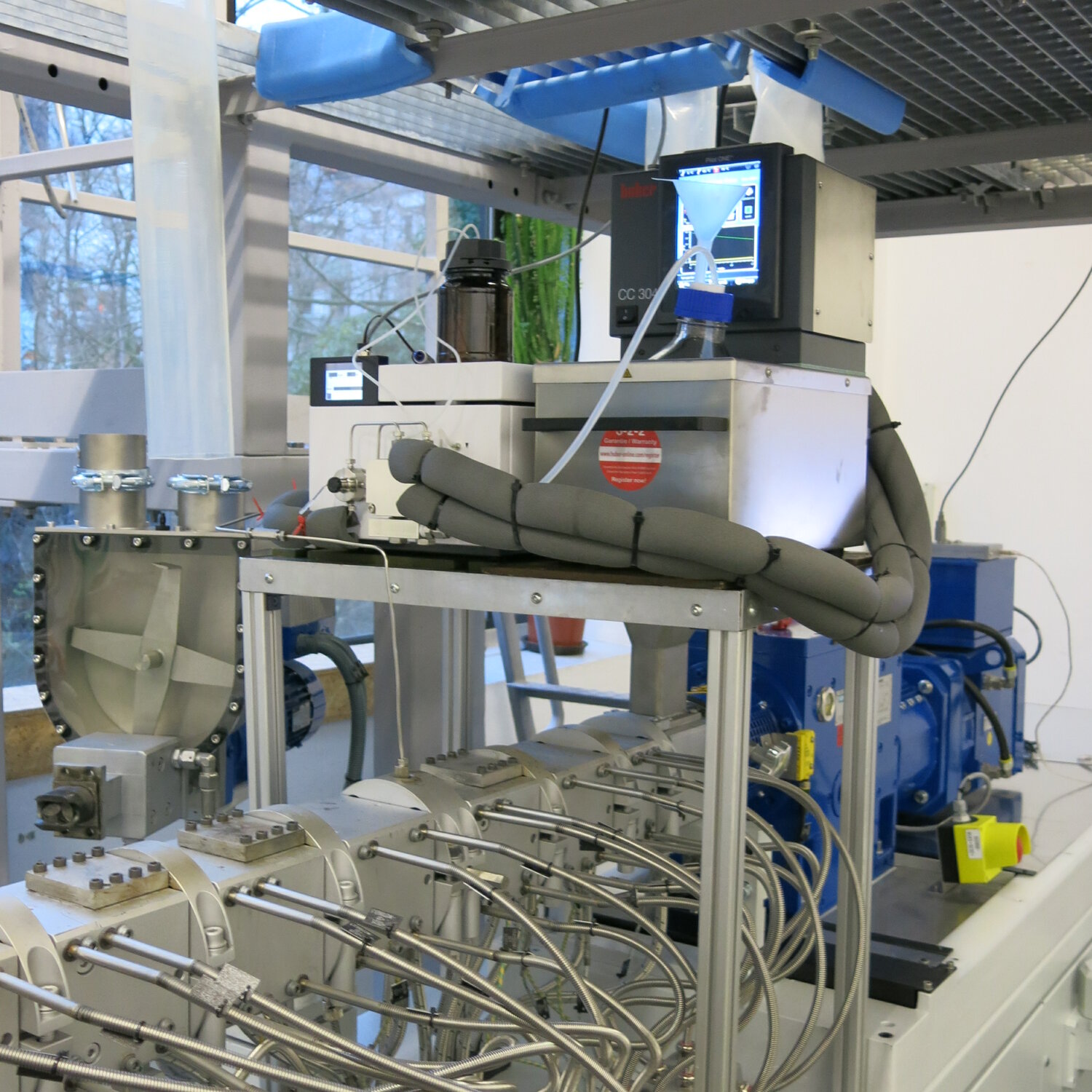

KNAUER dosing pumps are highly accurate two-piston pumps for applications in the chemical and pharmaceutical industries as well as in research and method development. They pump and dose aqueous and organic liquids, aggressive media or liquid gases. The metering pumps impress with their high chemical resistance, excellent flow rate precision and low pulsation of the pumped medium in a wide range of applications:

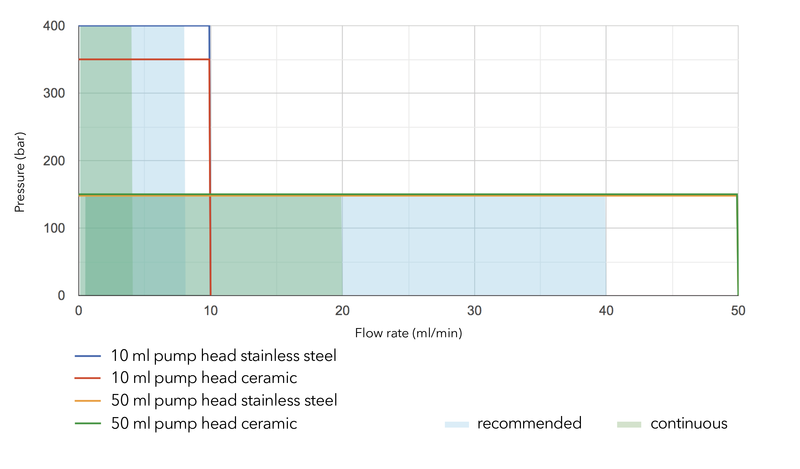

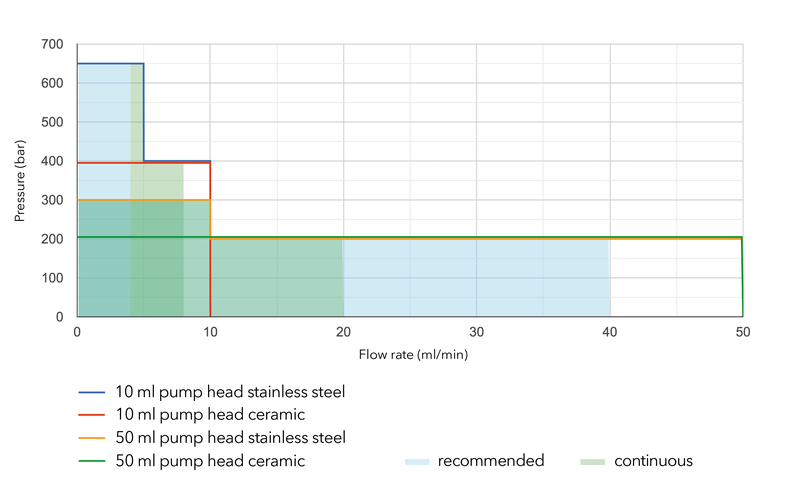

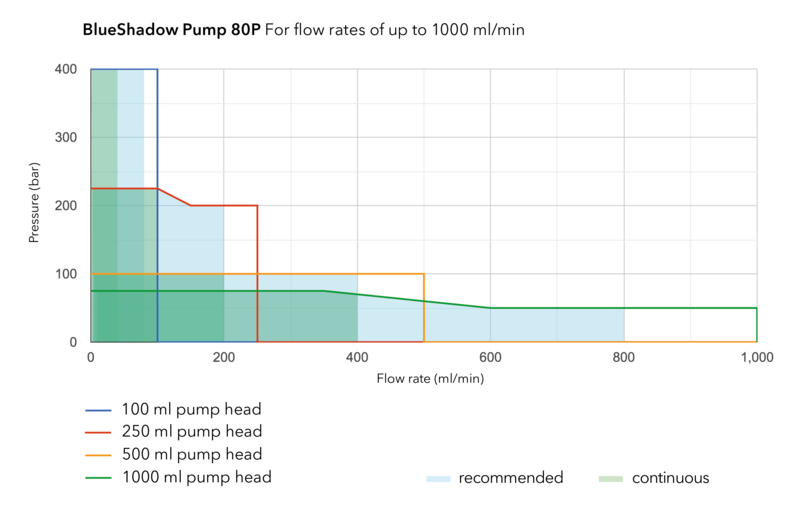

- Flow rates from 10 ml/min to 1,000 ml/min

- High pressure range up to 650 bar

- Wide temperature range from -10 °C to 120 °C

- Viscous liquids up to 1,000 mPa-s

Thanks to the integrated RFID-technology, pump heads are exchangeable for minimum downtime of your dosing solution while maintainig maximal flexibility with regards to flow and pressure range.

Get to know our versatile, powerful and precise dosing pumps. Fill out this form with your required parameters and we will get back to you with a pump recommendation.