Seasonal update on liquid handling

There is the German saying, “Der April macht was er will!” which in the figurative sense means that everything is unpredictable. Usually this is related to the weather but sometimes it applies to other areas as well.

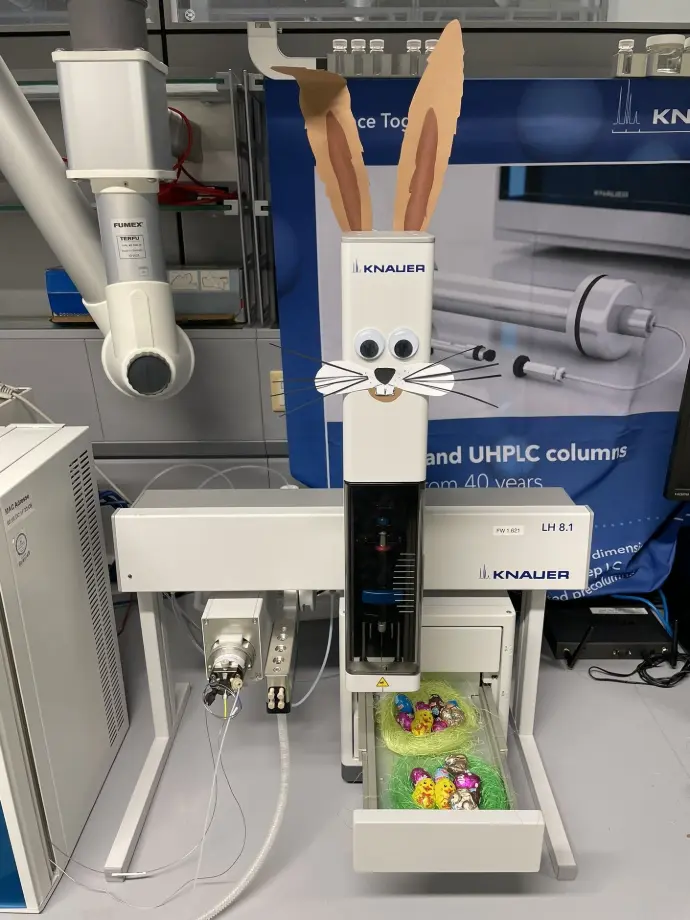

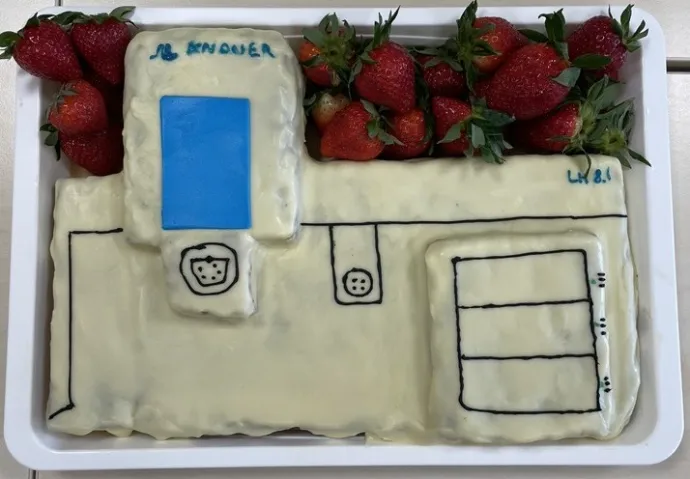

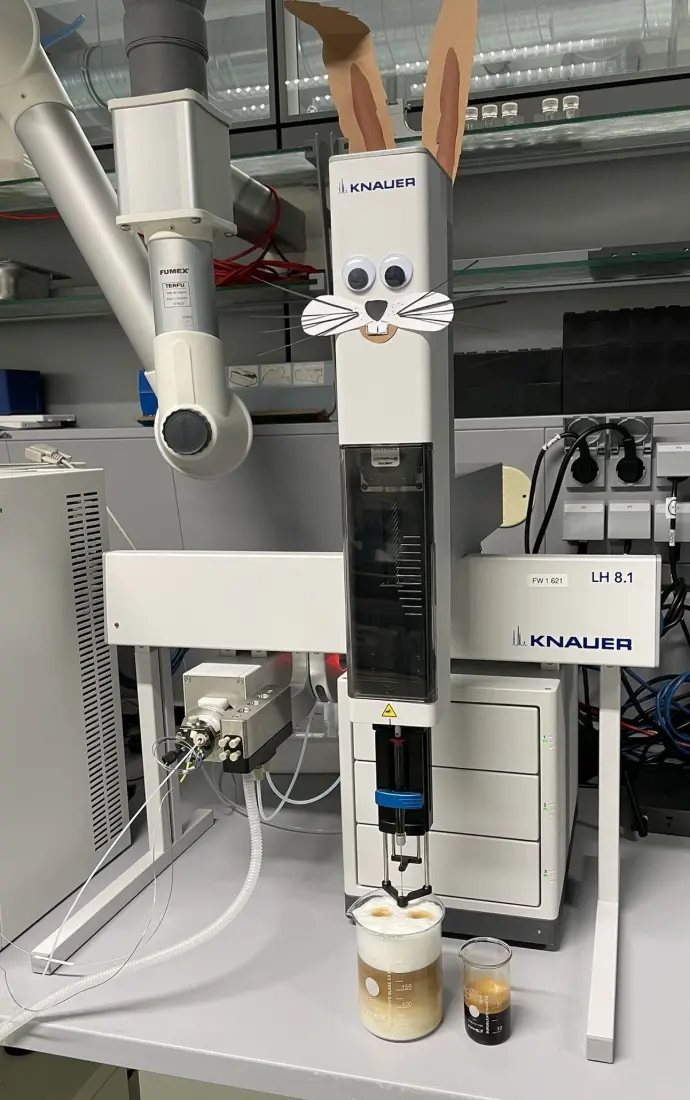

As one of KNAUER´s analytical application specialists, I was very excited when in the end of 2023, my favorite product manager Mareike Myrach and I were handed over the project of the Liquid Handler LH 8.1. We started out with no experience of this device, but soon we felt very comfortable as “teaching” ourselves was quite easy. After an extensive period of measurement and optimization, KNAUER officially launched the Liquid Handler LH 8.1 in April 2025. To come back to the German proverb: April is holding back, so far. On the contrary, it has even shown itself from the best side (not in terms of the weather!). Finally, we had all the documents together, all articles defined, all specifications fixed...it felt great. That made also our Liquid Handler in the lab very happy. There was even a delicious cake baked for this occasion. Yes, it is cake!

Fig. 1: Left: Happy Liquid Handler LH 8.1 (557mm Version), right: white “chocolate” Liquid Handler LH 8.1 (prototype, not for sale!)

But what is so special about the Liquid Handler LH 8.1? Let’s go through some of its features.

Flexible setup according to your needs

The KNAUER LH 8.1 is a customizable XYZ autosampler. It comes with a lot of different modules and accessories and is adaptable to your needs. In addition to the must-have modules such as the injection valve, the Robotic Cooler and the fast wash station, we are currently thinking about some special extensions. What do you think of our seasonal upgrade kits?

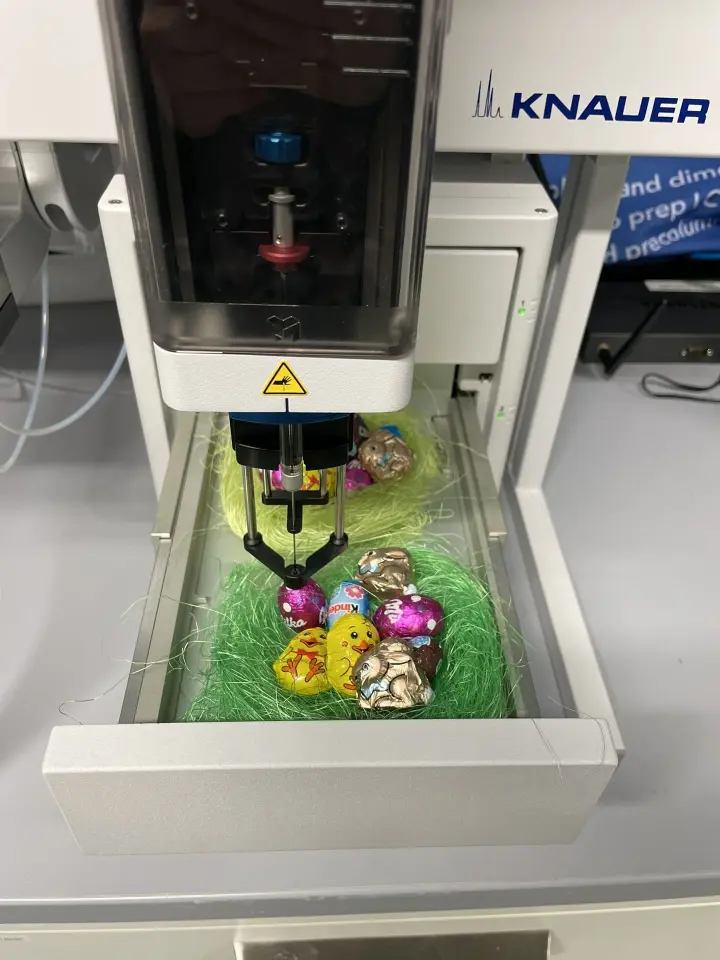

Fig. 2: Left: LH 8.1 Upgrade Kit “Easter”, right: LH 8.1 Upgrade Kit “Christmas” (only available in limited numbers (1 in stock))

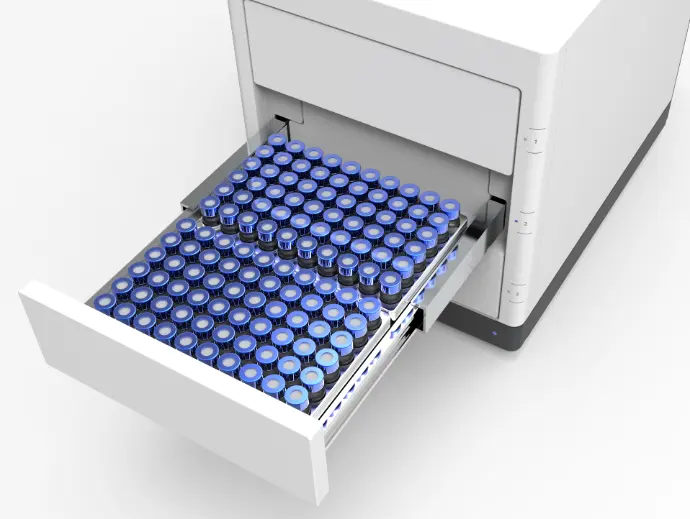

Variable sample storage and high throughput

The Robotic Cooler module is a must for high throughput analyses. You can insert up to 3 sample racks for 130 vials each, what means that up to 390 sample vials can be stored per Robotic Cooler. Depending on the rail length, a multitude of Robotic Coolers can be installed and used separately. Up to 3 Robotic Coolers on the longest rail what extends the sample capacity of one LH 8.1 device to up to 1170 x 1.5 ml vials. Of course, instead of commonly used sample vials you can also store other things between 4 - 40°C.

Fig. 3: Left: Tray with common samples, middle: tray with special samples, right: very, very special samples

True zero sample loss

Have you ever heard of sandwiches in liquid chromatography? Sounds a little strange, doesn’t it? Let’s change bread to common HPLC solvents and the filling to a sample. Add some small air gaps and bang... now we have a sandwich of liquids. But LH 8.1 is capable of so much more. You could basically build a sandwich from any type of vessel. Whether you use an ordinary vial or a filled chocolate egg, where the result is essentially an egg sandwich.

Please note that the carry over as well as the deliciousness will increase tremendously when injecting from such a sample container.

Fig 4: Left: Exemplary sandwich build-up, right: aspiration

from double coated chocolate sample container

Fig 4: Left: Exemplary sandwich build-up, right: aspiration

from double coated chocolate sample container

Carry over & injection precision

The first parameter to determine when you start talking seriously about HPLC injectors is injection precision. Fortunately, once we found the most suitable injection parameters, the results were excellent. Of course, we have incorporated all the parameters directly into the software drivers, so that any user can enjoy the same benefits as we do, without the need for complicated programming. The resulting values for injection precision can be set as follows.

Injection precision RSD (Relative Standard Deviation):

Full loop injection: ≤ 0.10 %

Sandwich injection at an injection volume

> 5 µl: ≤ 0.15 %

The next parameter to be considered very seriously is the value for sample carry over, using a recommended washing protocol. During the evaluation process, we determined the carry over of chlorhexidine using a standard procedure to obtain comparable results to other autosamplers on the market. In addition, we also tested caffeine carryover as this application is much more common in laboratories worldwide and sample accessibility is much better. Once again, we took advantage of the ability to sample from more unusual sample storage devices by simply teaching the LH 8.1.

Fig. 5: Exemplary sample take up for the determination of carry over. Left: injection of the diluted sample for quantification of caffeine, right: Injection of the high concentrated sample for carry over determination

We were able to determine the values as follows:

Sample carry over chlorhexidine: < 0.005

%

Sample carry over caffeine : < 0.002 %

Going back to the beginning of our blog post, you may have noticed that not only “der April macht was er will” but sometimes the KNAUER blog authors as well 😊 Despite the title, we hope you found more than one Easter egg and did not take everything too seriously.

More reputable information: KNAUER Liquid Handler LH 8.1

For further information on this topic, please contact our author: kramer@knauer.net, m.myrach@knauer.net