Science with Passion

Application No.: VTN0083 Version 1 12/2024

New high-pressure valve to switch between four columns for easy HPLC method development

Y. Krauke, M. Myrach, G. Greco; krauke@knauer.net

KNAUER Wissenschaftliche Geräte GmbH, Hegauer Weg 38, 14163 Berlin

Foto/3D-Rendering: KNAUER

Summary

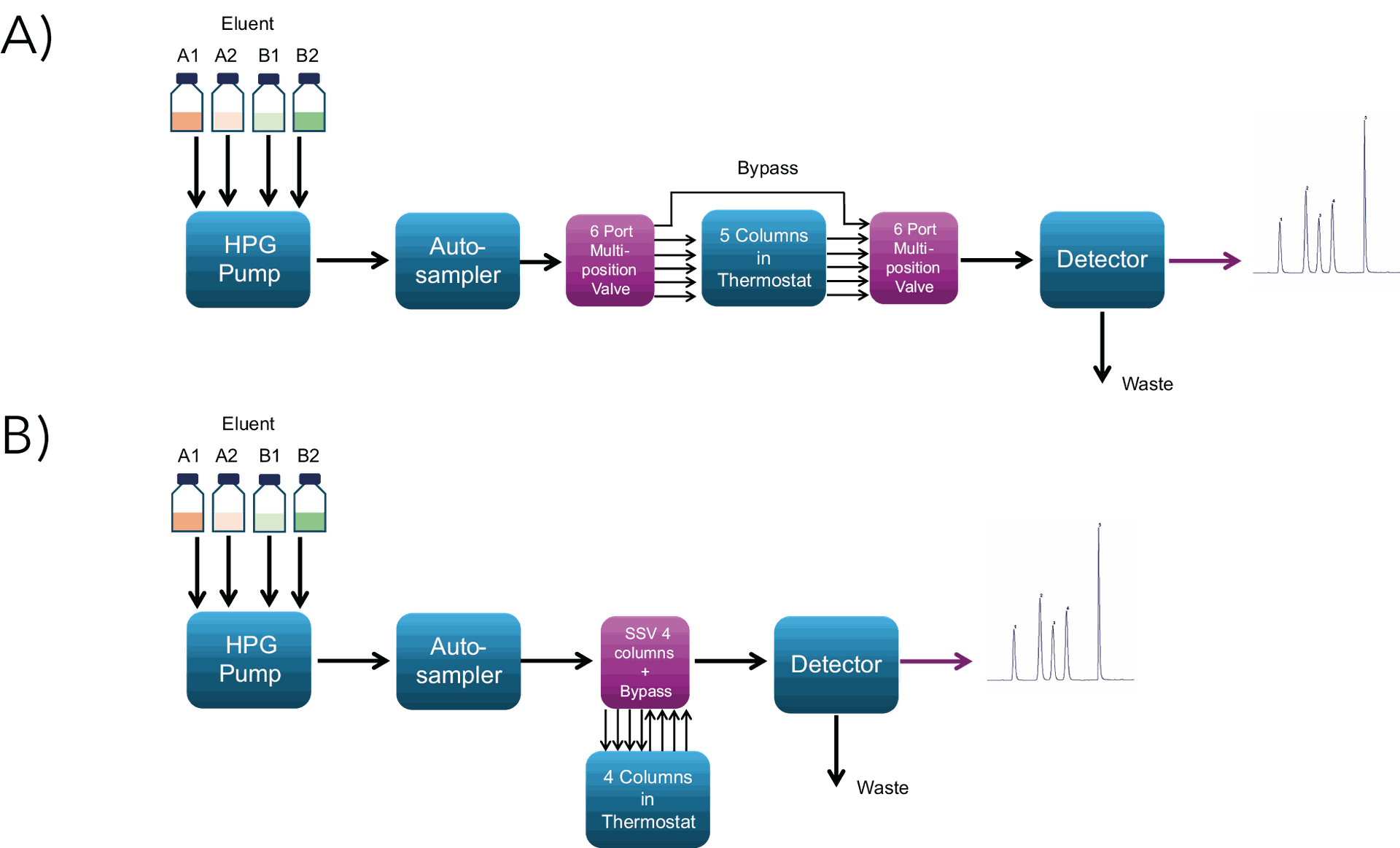

When developing an HPLC method, one of the initial steps involves screening a variety of columns to determine which offers the most effective separation of the analytes. While this can be performed manually, an automated approach is generally preferable, as it enables rapid switching between multiple columns within a short timeframe. Automated valve systems present a viable solution for this purpose. Two common configurations are employed: (1) using two multiposition valves with columns arranged between them, or (2) employing a specialized column switching valve designed to accommodate all columns simultaneously.

Here, we introduce a new high-pressure column switching valve capable of connecting up to four columns, in addition to providing a bypass path. To demonstrate its utility, the separation profiles of a standard mixture were evaluated on four different columns under two distinct solvent gradient conditions. This exemplary screening illustrates the advantages of employing a single column switching valve for method development and other applications that require efficient and reliable switching between multiple columns.

Introduction

A standard analytical HPLC system consists normally of a pump, detector, injection unit and one HPLC column which is often placed in a column thermostat. This set-up is sufficient for most applications, when only occasionally the column is exchanged by another column. During method development, where many different stationary and mobile phase are tested, this set-up lacks automatization and needs many manual interactions for changing the columns. Also, in lab environments where several methods with different columns are run with the same system, the standard set-up needs manual interaction.

The usage of several different columns can be automized by using a column selection valve. There are two possibilities to integrate several columns at the same time in an HPLC system: 1) by using two multiposition valves each mounted on its own valve drive, between which the columns are connected or 2) by using one special column selection valve with only one valve drive, to which the column in- and outlets are connected.

Here, the new KNAUER high pressure column selection valve is presented showing its advantages in automatization of a method development process. This solution makes it possible to switch automatically between up to four HPLC columns and offers one additional bypass option.

Sample Preparation

Standard mixes were prepared with 0.1 mg/ml concentration of each compound in methanol/water or acetonitrile/water and filtered through 0.2 µm syringe filters.

Results

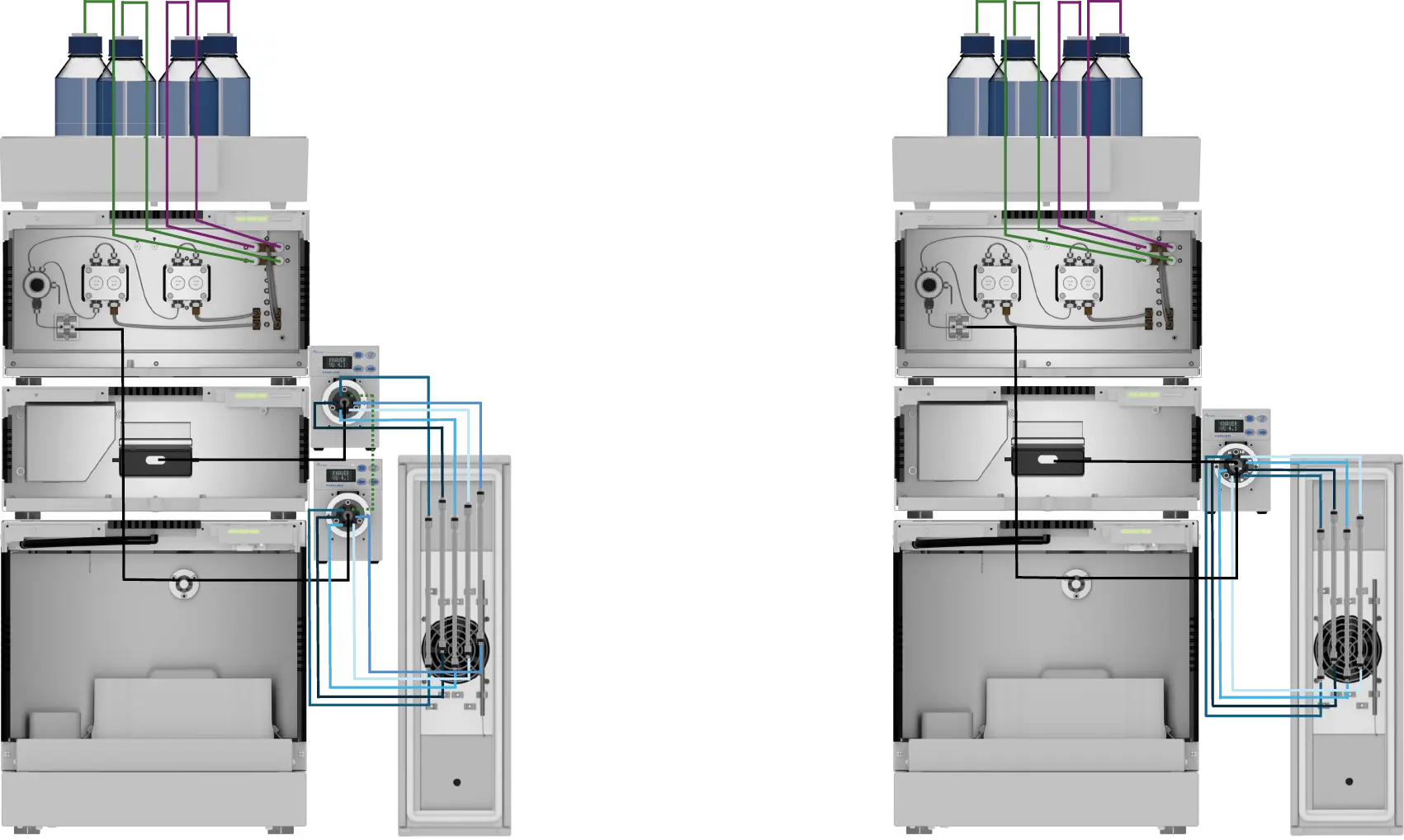

The classic approach to connecting more than one column to an HPLC system is to use two multiposition valves between which the columns are connected. For example, if two valves with six positions are used, five columns can be connected, and one position is used as bypass (Fig. 1, A). The latter allows flushing the system without disconnecting a column, for example when the eluent needs to be changed. The KNAUER HPLC system configuration for this set-up consists of a standard analytical HPLC and two external valve drives with six multiposition valves each (Fig. 2, A).

Another approach is to use a dedicated column switching valve where the in- and outlets of several columns are connected to one single valve, saving a second valve (Fig. 1, B). Therefore, the system set-up needs only one additional valve drive for the column switching valve to which up to four columns can be connected (Fig. 2 B). This valve drive can be placed on site of the system or above the column thermostat.

Fig. 1 Scheme system components for column selection. A) classic set-up with two 6 port multiposition valves B) optimized set-up with high pressure column selection valve

Fig. 2 Set-up analytical HPLC system for column selection with flow scheme. A) classic set-up with two 6 port multiposition valves B) optimized set-up with high pressure column selection valve

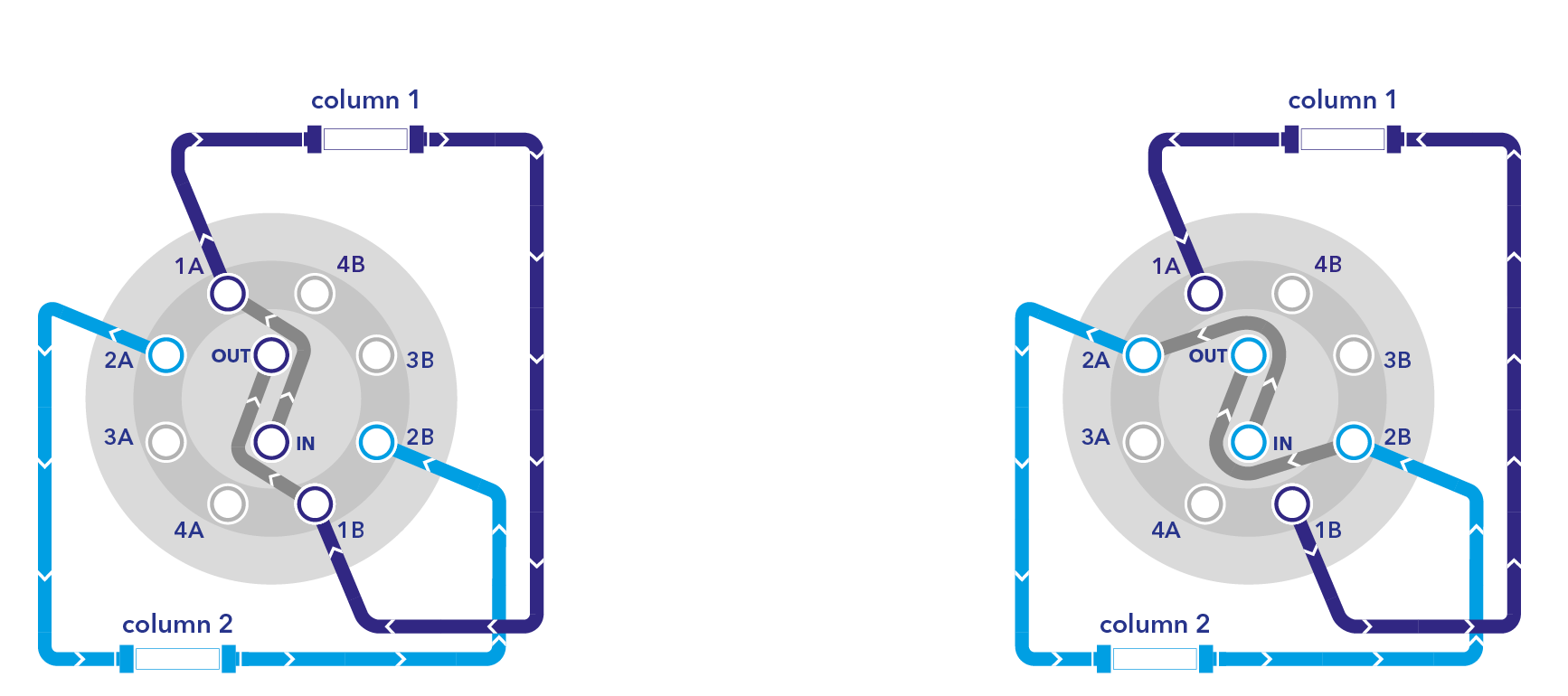

The KNAUER column selection valve consists of 10 ports, four pairs of two for connection of up to four columns and the “in” and “out” ports for connection to the HPLC system (Fig. 3). The capillary from the autosampler is connected to the 'in' port and the capillary to the detector is connected to the 'out' port. The corresponding port pairs for HPLC column installation are numbered from 1 to 4 and the addition A) for the capillary to the column inlet and B) for the connection to the column outlet. The valve can be switched between five positions, one for each column and a fifth which is the bypass. This allows the system to be flushed without passing through any of the columns.

Fig. 3 Connection ports of KNAUER column selection valve; 1) flow passes through column 1; 2) flow passes through column 2

There are two main applications for connecting multiple columns to one analytical HPLC system: 1) stationary phase screening for method development and 2) usage of multiple methods with different columns on one system.

Here, the column switching valve was used to highlight the automatization of a method development with stationary phase and solvent screening.

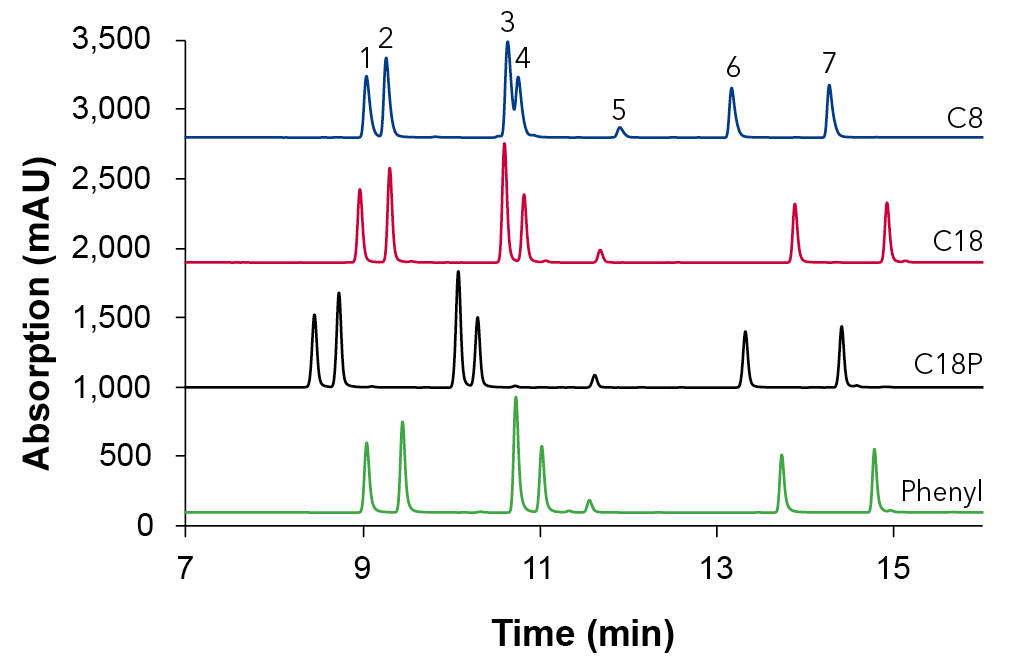

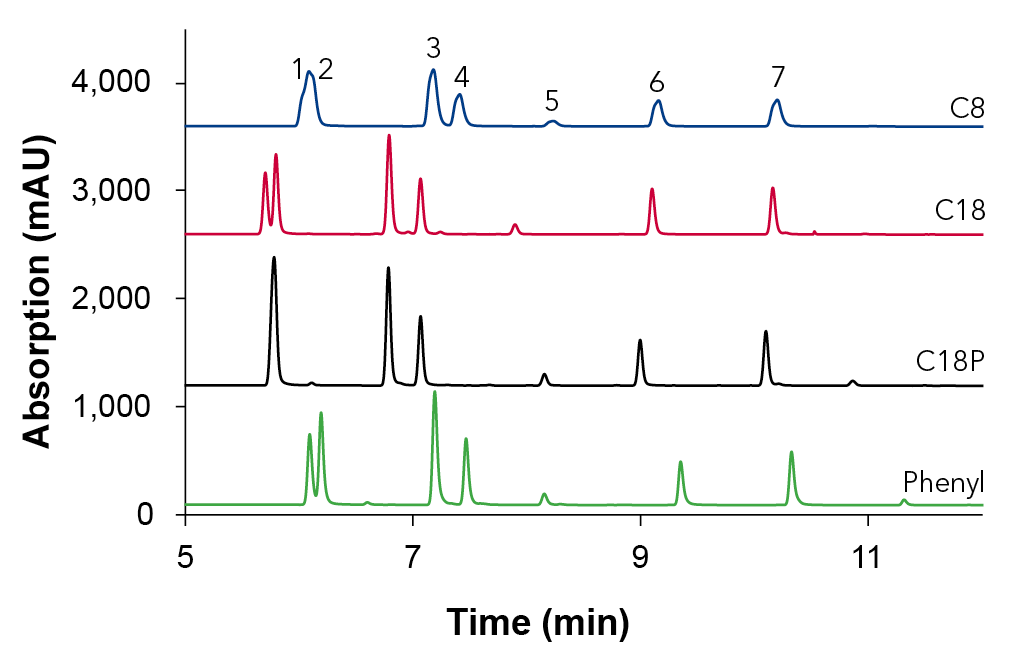

The separation of a mixture with seven standards (vanillic acid, syringic acid, p-coumaric acid, ferulic acid, benzoic acid, quercetin and kaempferol) was evaluated by using two different overview gradients 1) water / methanol and 2) water / acetonitrile testing four reverse phase columns of same dimensions (150 x 3 mm, 3 µm, 100 Å) but different modification: C8, C18, C18P and phenyl.

The separation profiles of the four different stationary phases were compared by overlaying the chromatograms. With the water/methanol gradient the C8 column had the weakest separation profile as p-coumaric and ferulic acid were not baseline separated (Fig. 4). The three other stationary phases showed baseline separation for all six standards. The C18P phase was the best suited as the retention times were lower allowing a faster analysis than the C18 and phenyl phase (Fig. 4).

Fig. 4 Overlay chromatograms with water/methanol; 1) vanillic acid, 2) syringic acid, 3) p-coumaric acid, 4) ferulic acid, 5) benzoic acid, 6) quercetin, 7) kaempferol; 4 µl injection, 0.6 ml/min, 25°C

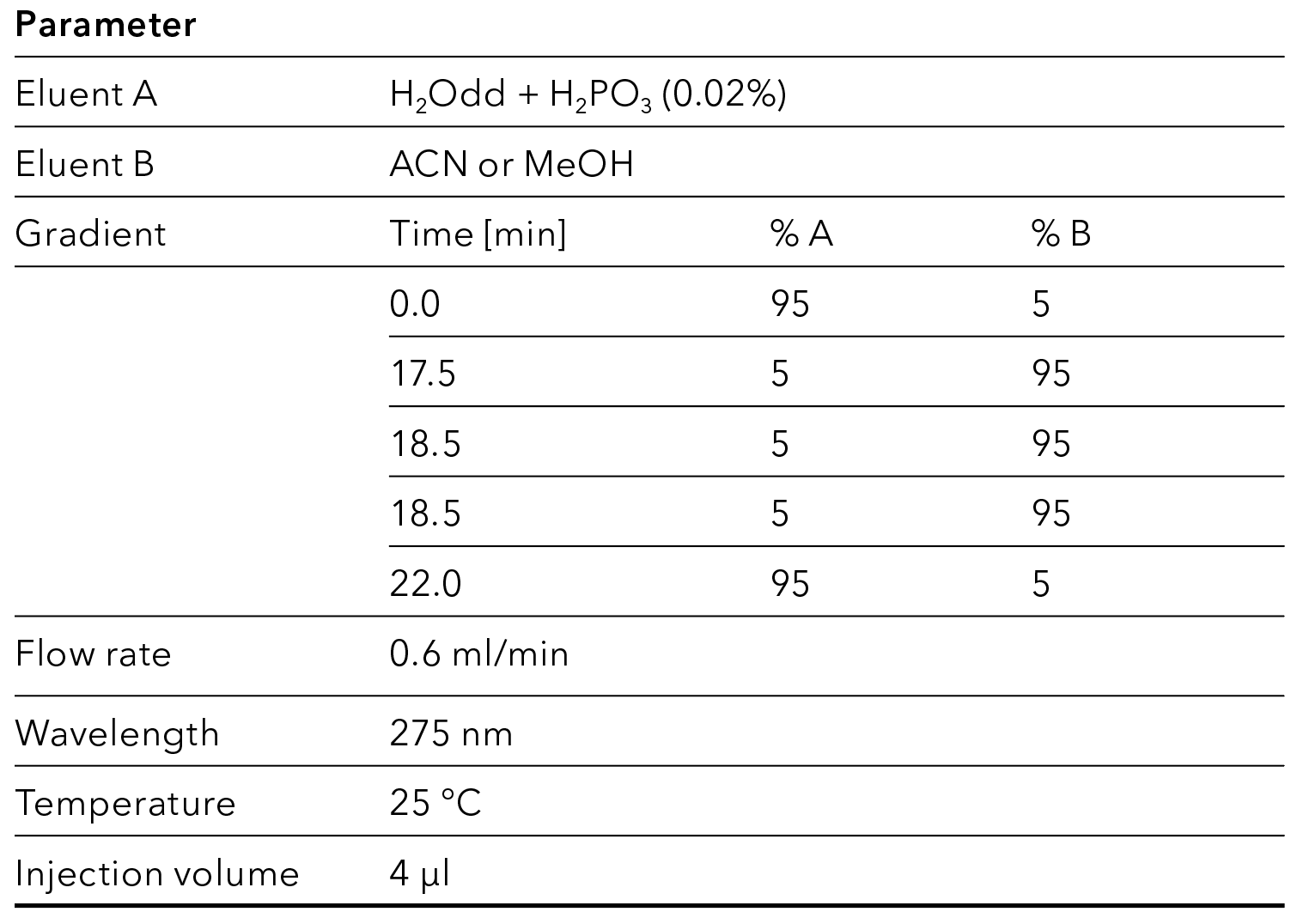

In the next step, a water / acetonitrile gradient was used for the same standard mix and stationary phases. The C8 and C18P phase showed no separation of the two first eluting compounds, vanillic acid and syringic acid. The phenyl and C18 phase separated all six standards with slightly shorter retention times with the phenyl phase.

Fig. 5 Overlay chromatograms with water/acetonitrile; 1) vanillic acid, 2) syringic acid, 3) p-coumaric acid, 4) ferulic acid, 5) benzoic acid, 6) quercetin, 7) kaempferol; 4 µl injection, 0.6 ml/min, 25°C

With the results from the two screenings, the optimal stationary and mobile phase were selected for the separation of the six compounds. The acetonitrile gradient led overall to shorter retention times and among them the C18 phase was the fastest.

Conclusion

The new KNAUER column selection valve was tested for its ability to automize method development. Here, four different stationary phases were tested and compared for their ability to separate a mixture of six compounds. Additionally, two different solvent gradients were tested. All presented screenings were measured in one sequence with no manual interaction highlighting the advantage of column selection valves for method development. Furthermore, additional solvents could be tested by adding one or more solvent selection valves to the system pump. The advantage of the column selection valve compared to a set-up with two multiposition valves is that only one valve drive and valve are needed reducing the system costs and space needed.

Material and Methods

Tab. 1 Analytical method parameters

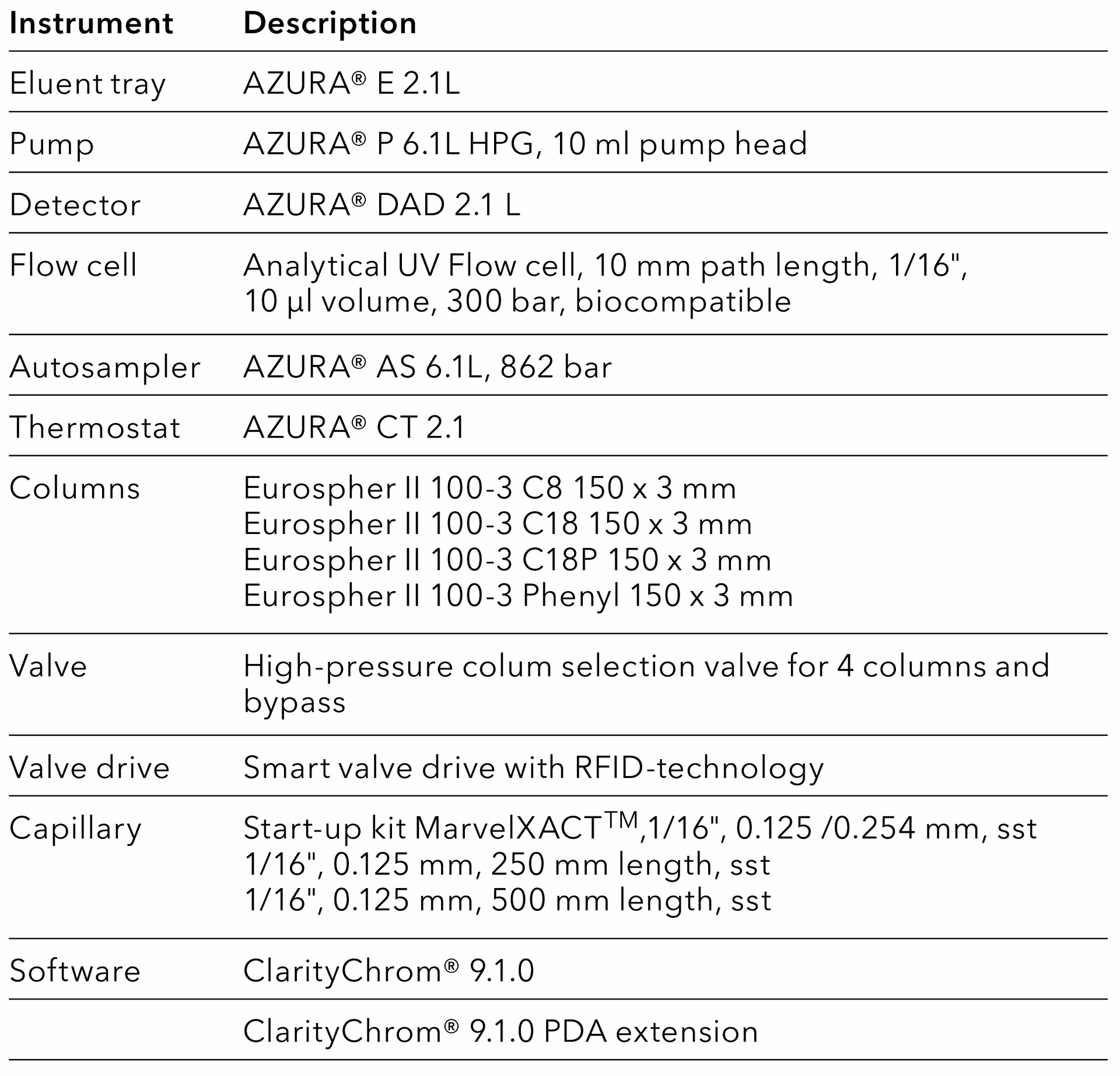

Tab. 2 Analytical system configuration

Application details

Method | HPLC |

Mode | RP |

Substances | Vanillic acid, syringic acid, p-coumaric acid, ferulic acid, benzoic acid, quercetin, kaempferol |

Key words | Column selection valve, method development, solvent screening, stationary phase screening, automatization |

CAS number | 121-34-6, 530-57-4, 501-98-4, 1135-24-6, 65-85-0, 117-39-5, 520-18-3 |

Version | Application No.: VTN0083 | Version 1 12/2024 | ©KNAUER Wissenschaftliche Geräte GmbH |