Science with Passion

Application No.: VTN0041 Version 1 03/2025

Sandwiches for all – benefits and injection principles of the KNAUER Liquid Handler LH 8.1

J. Kramer, M. Myrach, G. Greco; kramer@knauer.net

KNAUER Wissenschaftliche Geräte GmbH, Hegauer Weg 38, 14163 Berlin

3D-Rendering: ModuVision/KNAUER

Summary

Sandwiches in liquid chromatography? Sounds a little strange, doesn’t it? Generally, a sandwich can be described as any dish in which bread serves as a container or wrapper for a filling. Let’s change the bread to common HPLC solvents and the filling to a sample. Add some small air gaps and bang ... now we have a sandwich of liquids.

Introduction

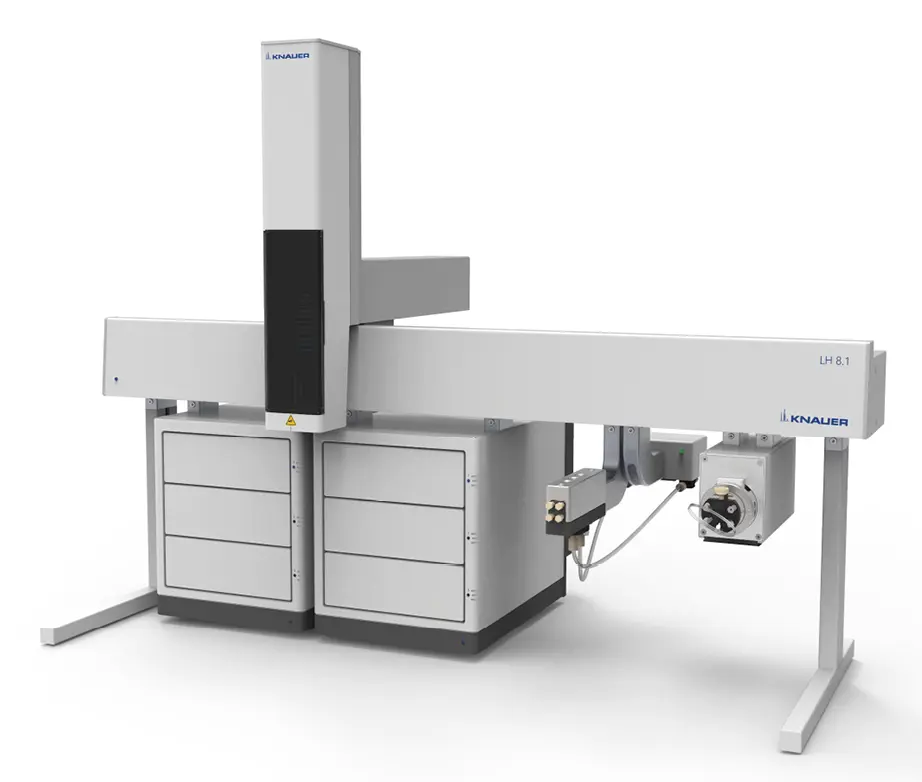

The KNAUER LH 8.1 is an analytical, modular and customizable XYZ autosampler (Fig. 1). It combines the main functions of an autosampler, sample storage and sample injection, with additional options for high sample capacity, customizability, liquid handling and sample preparation.

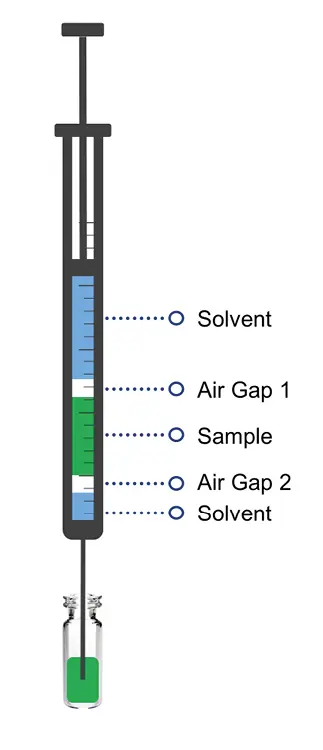

Using sandwich mode means that only the amount of sample that will be injected is aspired by the syringe. The sample is trapped between air gaps and transport solvent plugs (Fig. 2), preventing peak broadening already during the injection process. This injection mode provides very high precision and none of your sample gets lost.

Fig. 1 LH 8.1 in 557 mm version in combination with an AZURA Analytical HPLC system

One of the features of the LH 8.1 is the “Sandwich” injection mode.

Fig. 2 Schematic illustration of sandwich build-up in the syringe

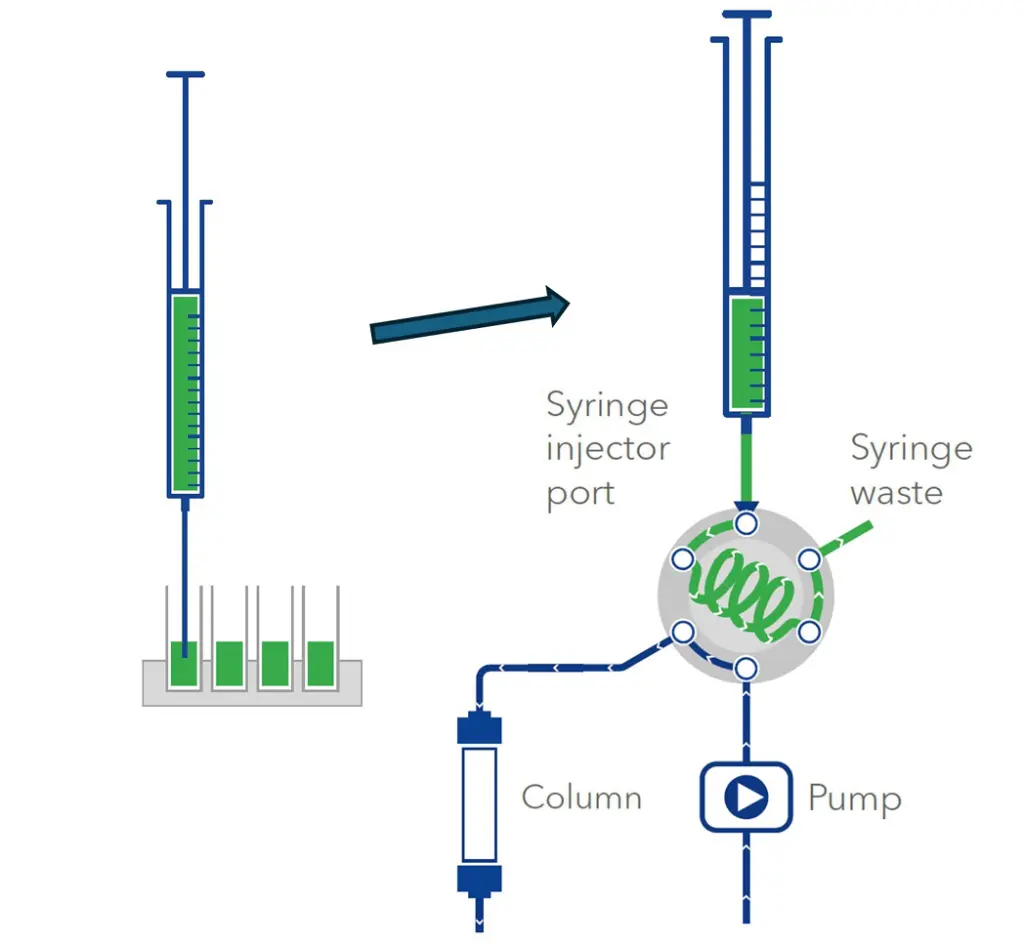

LH 8.1 supports also “Full Loop” injection mode. Here, the sample loop is filled completely with the sample and maximum injection precision is achieved (Fig.3).

Fig. 3 Schematic illustration of full loop injection

With the exemplary separation of uracil, paracetamol, theophylline and caffeine we show that also HPLC can make sandwiches.

Sample preparation

Single standards were weighed in and dissolved with 100 % methanol. Stock solutions of β=1 mg/ml for each compound were prepared. A mixed standard with all four analytes was diluted with 40 % methanol to a concentration of β=0.05 mg/ml for each compound. An injection volume of 5 µl was used for all measurements.

Results

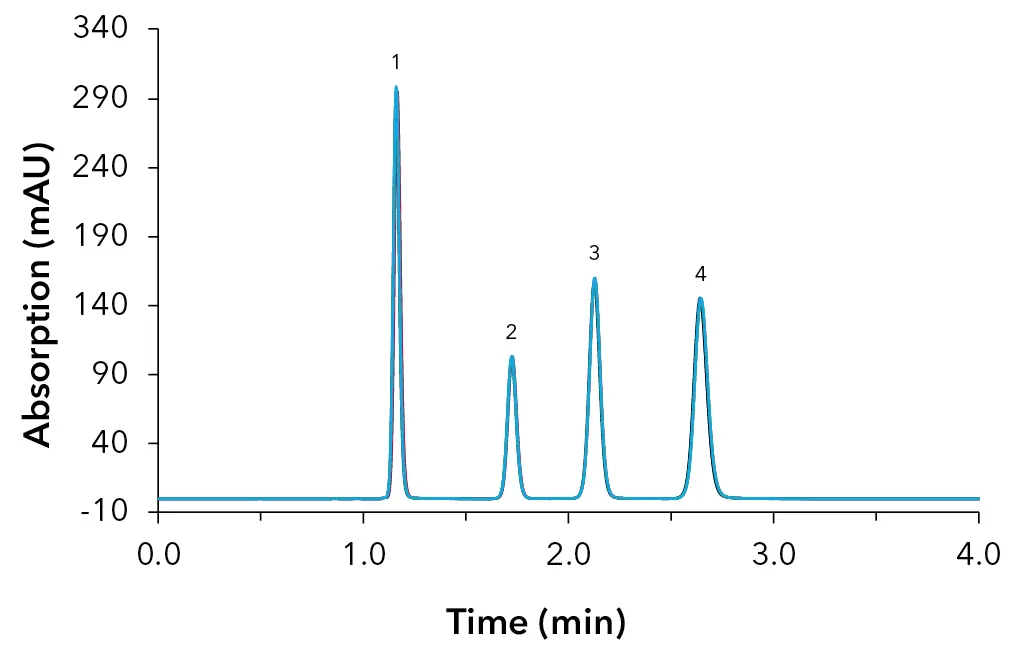

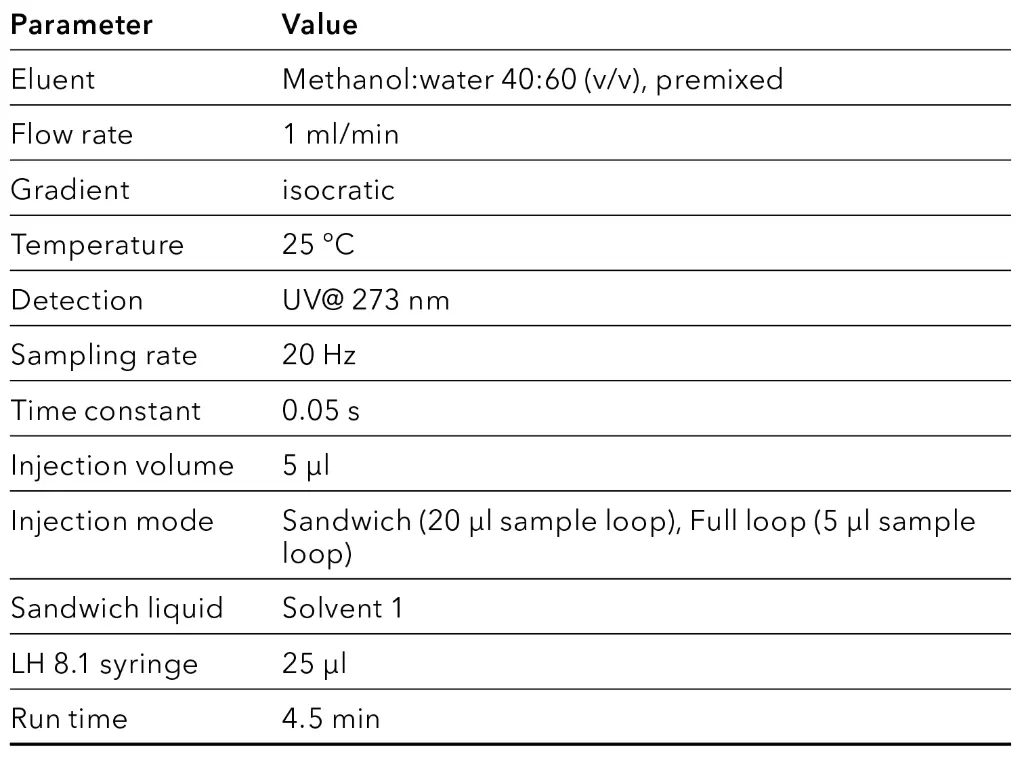

The mixed standard was separated under isocratic conditions with a mixture of methanol:water 40:60 (v/v). All analytes are baseline separated. Figure 4 shows an overlay of five injections with the sandwich injection mode.

Fig. 4 Overlay of five replicates with sandwich injection mode, (1) uracil (2) paracetamol (3) theophylline (4) caffeine

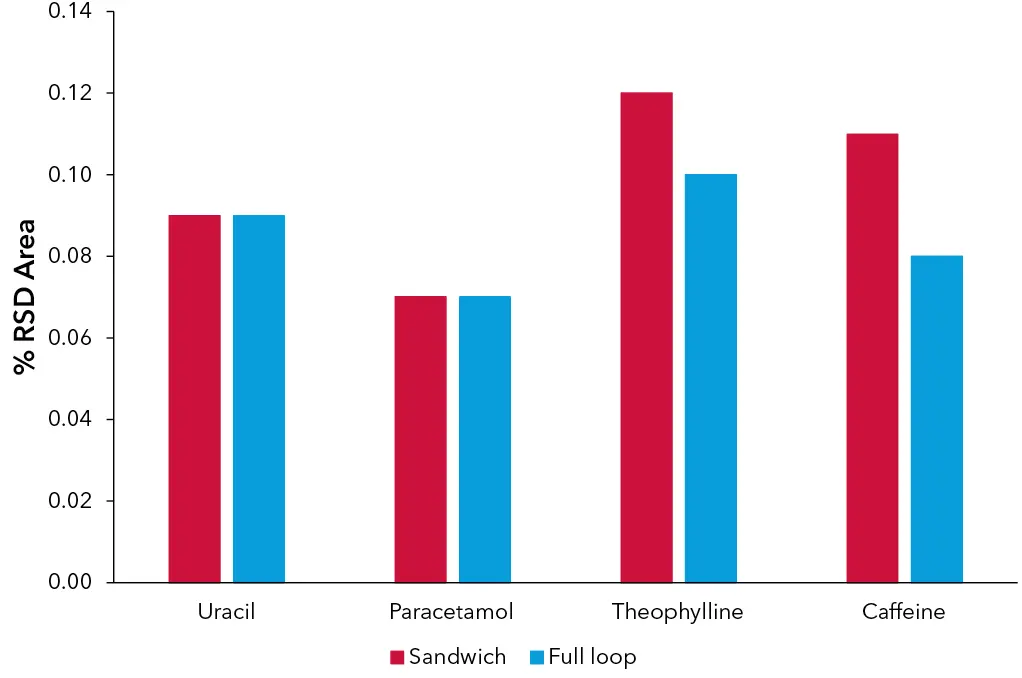

The measurements were also carried out using full loop injection mode. The following chart (Fig.5) compares the relative standard deviation of the peak area for both used injection modes.

Fig. 5 Comparison of relative standard deviation of peak area, red – sandwich injection, blue – full loop injection

For both injection modes the relative standard deviation (% RSD) for peak area was below 0.13 % for all peaks in this exemplary application. The values for full loop injection showed slightly better results.

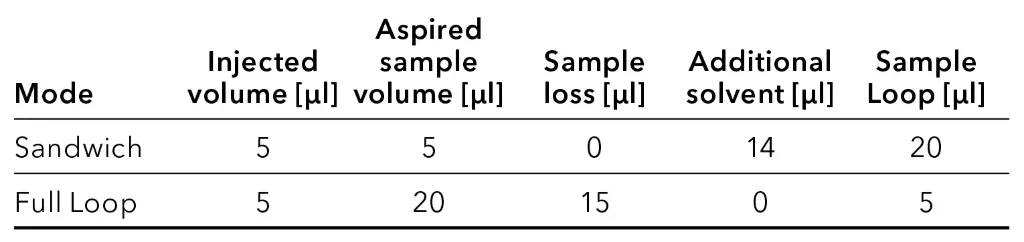

This injection mode is known to give maximum repeatability if a sufficient overfill of the loop is programmed. In our case, the fourfold overfill gives the highest injection precision, but also requires a large sample volume. The amount of used and lost sample for an injection volume of 5 µl is summarized in Table 1.

Tab. 1 Sample consumption for sandwich and full loop injection

Conclusion

The liquid handler LH 8.1 combines the benefits of a “traditional” liquid handler and an autosampler.

Modular design, high sample capacity as well as outstanding analytical performance are only some of the customers’ benefits. The sandwich injection mode provides the same values for repeatability as a full loop injection but without any sample loss. Finally, we were able to show that sandwiches are a good choice, also in HPLC.

Material and Methods

Tab. 2 System configuration

Instrument | Description | Article No. |

Liquid Handler | LH 8.1 Liquid Handler, 557 mm version with Robotic Cooler, including injection valve and fast wash station | |

Syringe for both injection modes | Hamilton X-Type 25µL PTFE Tip, fixed needle 22s gauge | |

Pump | AZURA P 6.1L Low Pressure Pump, | |

Detector | AZURA Detector DAD 2.1L, 190 – 700 nm | |

Flow cell | Standard KNAUER LightGuide UV Flow Cell Cartridge | |

Thermostat | AZURA CT 2.1 | |

Column | Eurospher II 100-5 C18, Column 150 x 4 mm | |

Software | ClarityChrom 9.1.0 - Workstation, | |

Software | ClarityChrom 9.1.0 - System suitability extension (SST) |

Tab. 3 Method settings

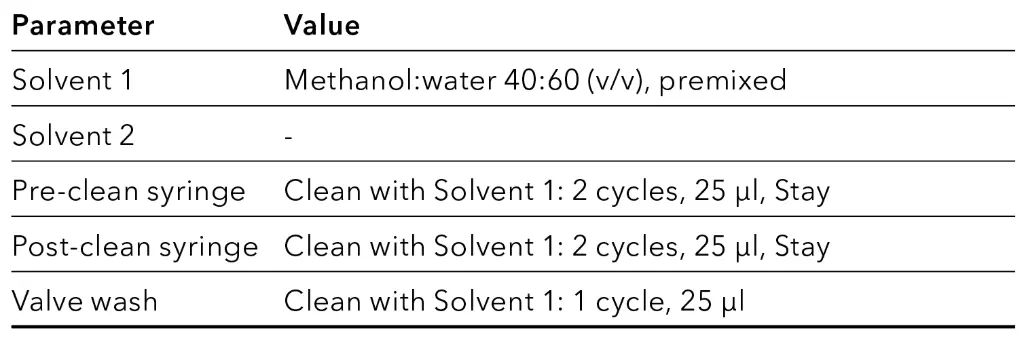

Tab. 4 LH 8.1 wash settings

Application details

Method | HPLC |

Mode | RP |

Substances | Uracil, Paracetamol, Theophylline, Caffeine |

Key words | Column selection valve, method development, solvent screening, stationary phase screening, automatization |

CAS number | 58-08-2, 103-90-2, 58-55-9, 66-22-8 |

Version | Application No.: VTN0041 | Version 1 3/2025 | ©KNAUER Wissenschaftliche Geräte GmbH |