Principle of Manual Injection

Most important factors in injection are precision, accuracy and carryover. They are effected by the injection technique and equipment and for manual injection also by the user.

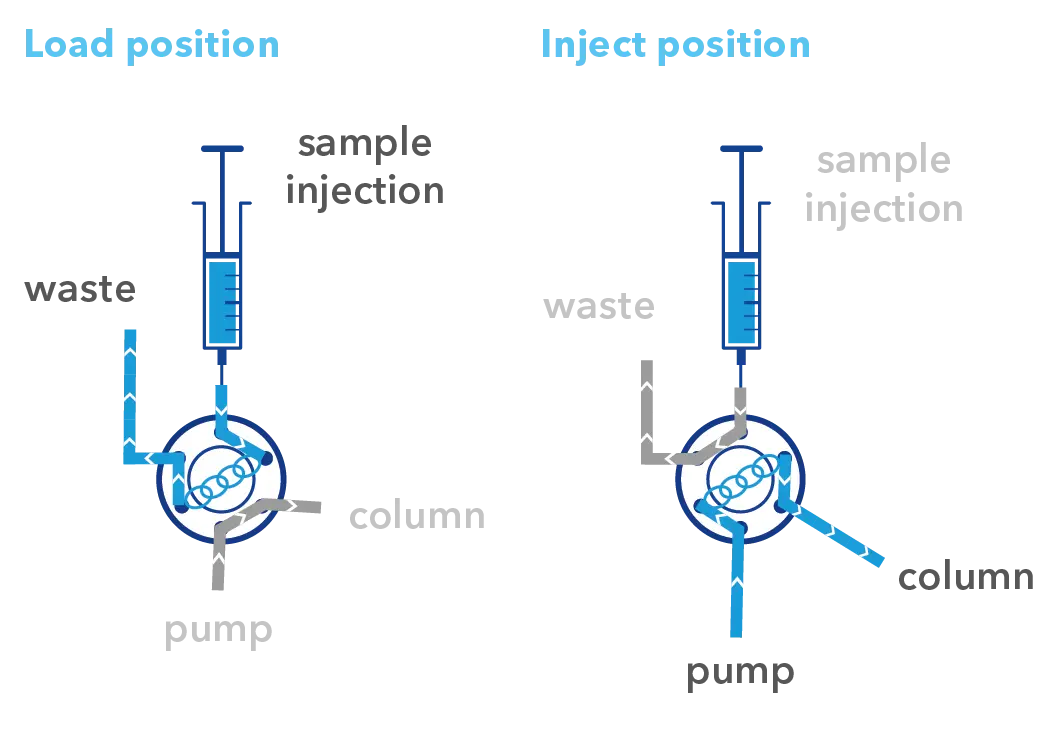

In the load position a sample loop is filled with sample while the system is equillibrating. When turning to the inject position, the sample loop is switched to the high pressure part of the HPLC system. The flow delivered by the pump flows through the loop and feeds the sample onto the column.

Manual injection valves are the most cost-effective option to introduce samples. Normally, valves with 6 ports and 2 positions – for loading and injection – are used.

Injection Valves

The simplest way to inject your sample into the system. Use a manual injection valve and choose from a large range of different sample loops, available for different applications.

For analytical HPLC, our valves feature a wide back pressure range of up to 1200 bar with a 0.3 mm bore size. All valves can be equipped with an automatic valve drive.

For protein purification, the AZURA® 2-positions valve is perfect for injection of small sample volumes. Connect 1/16" tubings for flowrates up to 100 ml/min. For higher flowrates use the injection valve for 1/8" tubing. Various sample loops are available. The FPLC injection valve can be integrated or act as a standalone module.

REQUEST A QUOTE

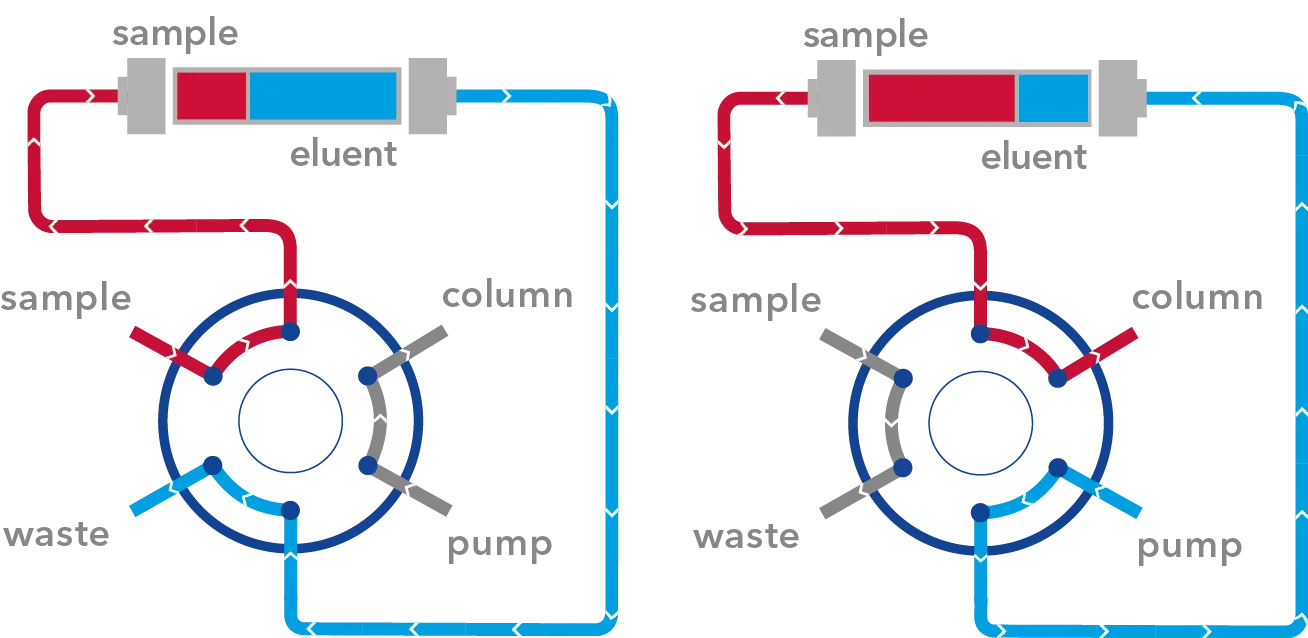

VariLoop for Sample Injection

The KNAUER VariLoops are the perfect solution for the injection of medium up to high sample volumes (up to 40 ml). The sample loop can be emptied completely or partially as well as filled completely or partially. This allows you to work very flexible and easily switch between different sample sizes while keeping constant and reproducible injection volumes for every sample size.

Automated Sample Injection

Autosamplers also work with an injection valve and a sample loop, but unlike a basic valve/loop combination they can process a large number if different samples and they often feature additional injection modes like 'partial loop fill' or 'microliter pickup'. For automated injection autosamplers are a common choice, but so-called liquid handlers can also do the job, because they combine fractionation and injection capability in one device. Autosamplers and liquid handlers offer high precision and accuracy.

Autosamplers also work with an injection valve and a sample loop, but unlike a basic valve/loop combination they can process a large number if different samples and they often feature additional injection modes like 'partial loop fill' or 'microliter pickup'. For automated injection autosamplers are a common choice, but so-called liquid handlers can also do the job, because they combine fractionation and injection capability in one device. Autosamplers and liquid handlers offer high precision and accuracy.

- Autosamplers come in 'flavors' for analytical HPLC, preparative LC or FPLC sample injection. For example the Autosampler AS 6.1 analytical can hold up to 108 standard 2 ml sample vials, but can also inject up to 768 samples from well-plates. An Autosampler AS 6.1 preparative can inject up to 10 ml per injection, of which it holds a maximum of 30 samples. Sample tray temperature control from 4–40°C is optionally available.

- Liquid handlers are also available in different sizes: e.g. an analytical size LH 8.1 or the preparative size LH 2.1.

REQUEST A QUOTE

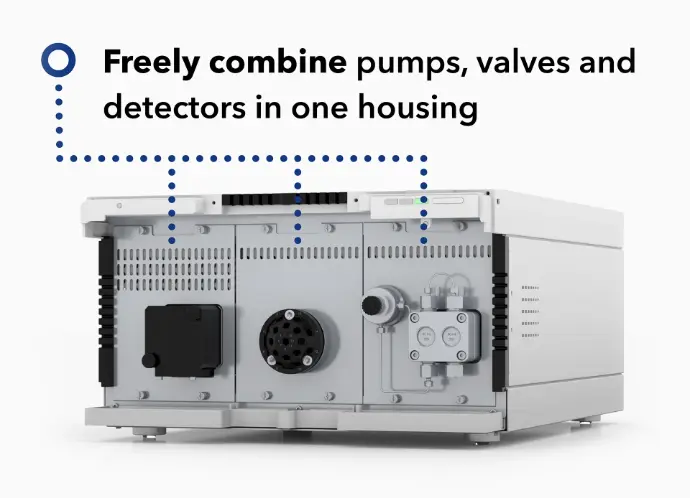

Sample Injection Assistant

The sample injection assistant for preparative LC is designed to automate injection of larger sample volumes. It features a sample selection valve, a sample pump, and an injection valve. Simply attach your sample vessels via 1/8" tubing to the multiposition valve and automate injection with the integrated sample pump and injection valve. The AZURA® sample injection assistant for preparative LC is based on the multifunctional AZURA® element ASM 2.2L and can be configured according to your needs. Analytical HPLC sample injection assistants as well as assistants for protein purification (FPLC) are available.

Sample Pump

Standalone or integrated in an assistant module ASM 2.2L: The compact pump AZURA® P4.2S is perfect for feed injection or for injection of larger sample volumes. Repetitive sample injections by using the pump for automated sample loop filling.

Do you have many samples? You can extend your configuration with additional valves each for up to 8 samples.

Our lab experts have designed different pump specifications according to the desired application. We will help you to find your perfect set up. We can even test your application in our lab, to provide you a verified product suggestion. Do not hesitate to contact us.

For preparative chromatography, we recommend a sample pump with 10 and 50 ml exchangeable pump head. The pump heads are available in stainless steel or ceramics.

Flow rate range:

- 0.01 – 50 ml/min (50 ml pump head)

- 0.001 – 10 ml/min (10 ml pump head)

Best working conditions:

- 1 – 40 ml/min (50 ml pump head)

- 0.1 – 8 ml/min (10 ml pump head)