System specifications need an update

In years past, buying an HPLC meant looking for the best system performance at the best price. You look at pump pulsation, injection reproducibility, detection options, and that's about it. But then we learned about something called cost-per-run.

We were asked by upper management to bring in data to show the return on investment over the long term.

How do you calculate how much it costs to run a sample now and 3-5 years from now? You have to look at the analysis holistically and include some recurring costs in your calculation, such as solvent consumption, labor costs, columns, to name a few.

However, these parameters are not enough to provide a complete picture. The energy consumption of the HPLC system and the product lifetime, i.e. how often you can repair your system, and the supplier can guarantee the availability of spare parts after several years, have a huge impact on the cost per run.

Photo/Graphic by KNAUER

Sustainability is not a trend at KNAUER. Since the start of the company in 1962, every decision, such as for example the selection of the suppliers or the design of the products, is driven by offering to the user long lasting products, with a minimal impact on the environment. The longer a system is in use, the less environmental impact does its shipping have", says Dr. Kate Monks, Head of Quality & Regulatory.

How to calculate the user impact of HPLC systems

Energy consumption and product lifetime are not easy to find in user manuals or product specification sheets. So how can a user make a conscious purchase? My Green Lab is a non-profit organization that aims to fill this gap. Their goal is to encourage lab users to discover and implement sustainable practices in their daily scientific work. In 2017, they launched a program for the US and in 2018 for the UK and Europe called ACT® Label. ACT stands for Accountability, Consistency, and Transparency, and the label aims to provide a clear and transparent assessment of the manufacturing, energy and water use, packaging, and end-of-life of laboratory products. ACT-labeled products are independently verified by SMS Collaborative, LLC (SMSC) and published by My Green Lab.

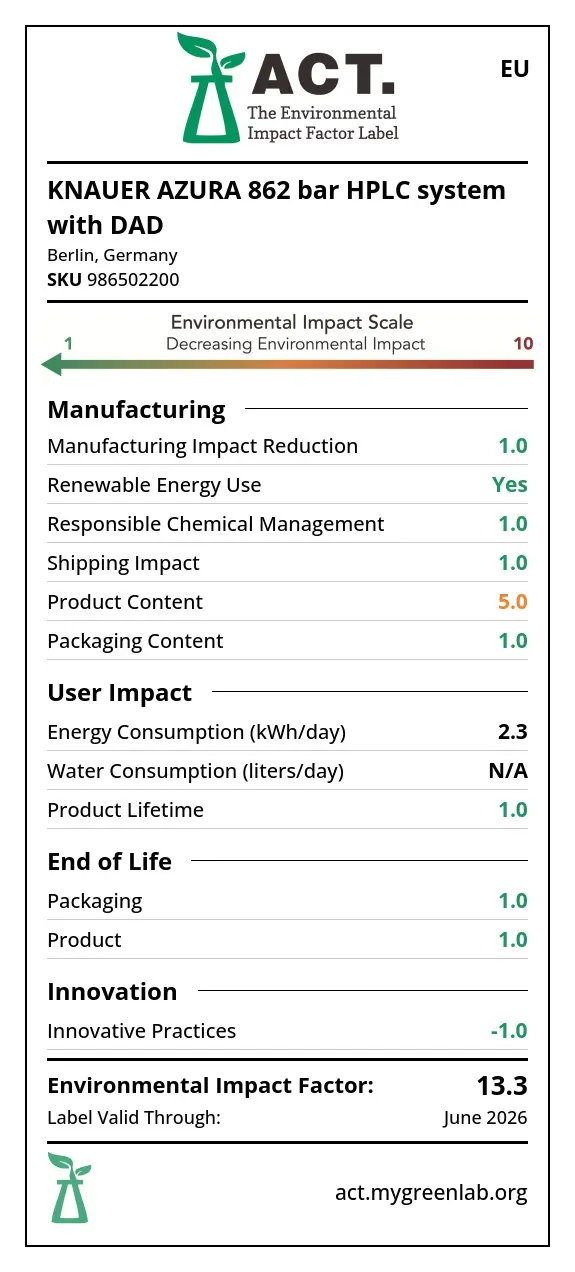

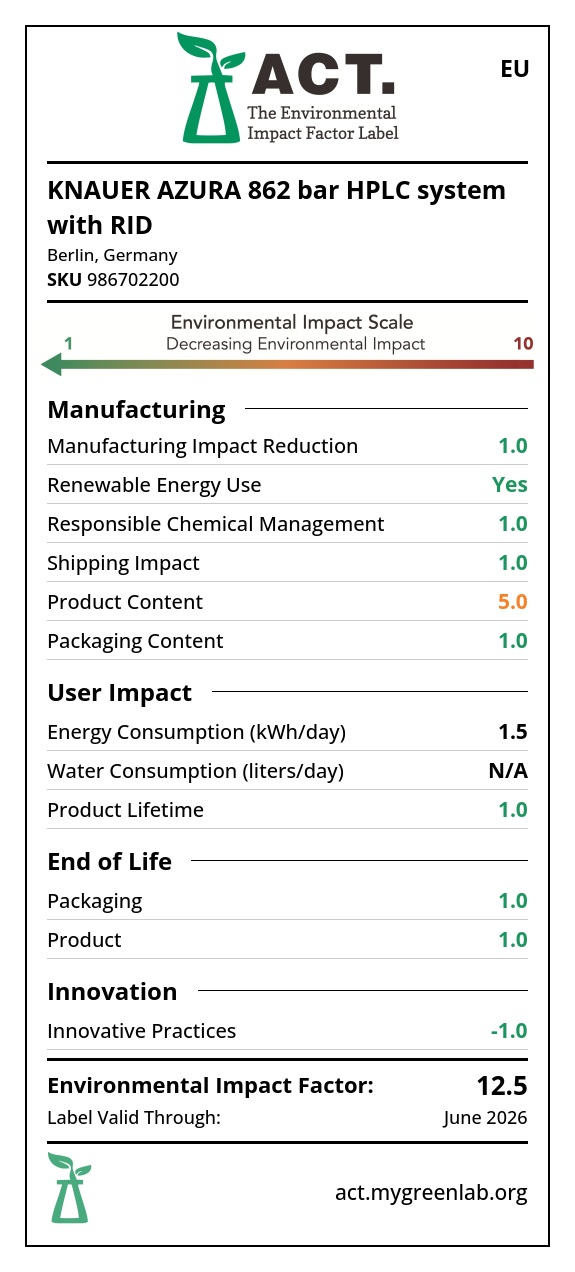

The ACT label consists of four categories: Manufacturing, User Impact, End of Life, and Innovation. Each category has several subcategories that are scored from 1 to 10. The sum of the scores for each subcategory is the product's Environmental Impact Factor. The lower the overall score, the lower the environmental impact.

The ACT label finally provides new transparent criteria to evaluate and compare laboratory products and help laboratory users and managers to make conscious purchases, not just based on technical specifications.

KNAUER HPLC systems have the best ACT label on the market

Here at KNAUER, we take sustainability very seriously. For us, sustainability is not just a new trend, but the guiding principle behind every decision we make.

Therefore, we have decided to submit our two best-selling HPLC systems, the KNAUER AZURA® 862 bar system with DAD and the KNAUER AZURA® 862 bar system with RID, for ACT Label certification.

It is with great pleasure and pride that we announce that KNAUER's best-selling HPLC systems have received the best Ecolabel compared to all other HPLC products currently (July 2024) in the ACT database. (https://www.knauer.net/corporate-social-responsibility ).

KNAUER AZURA 862 bar HPLC system with DAD - ACT Eco Label: https://actdatabase.mygreenlab.org/details/1251

KNAUER AZURA 862 bar HPLC system with RID - ACT Eco Label: https://actdatabase.mygreenlab.org/details/875

If you want to learn more about the journey that KNAUER did to achieve the My Green Lab ACT Ecolabel read the blog here:

For further information on this topic, please contact our author: Dr Giorgia Greco greco@knauer.net