… a whole (U)HPLC system without tools and trouble

How long does it take to install all the capillaries and fittings on a standard HPLC system?

My answer to this question depends entirely on the time frame in which it was asked. Let me explain why.

I started working with HPLC more than 15 years ago. It was an exciting time, as it marked the transition from classical HPLC to UHPLC systems for standard end users. I know how it is when you're just starting out – you're only allowed to work on the most robust classical HPLC systems at first, right? Well, that was definitely the case for me in my lab, but I soon became the go-to person for our UHPLC equipment. As we were doing a lot of method development and changing our systems regularly, installing capillaries and fittings to connect everything was one of my main tasks and took up most of my time. I'd say I'm pretty experienced when it comes to capillaries and connections.

Today, as product manager for analytical HPLC and UHPLC systems here at KNAUER, I am in the fortunate position of deciding which type of capillary type I recommend to my colleagues and to every user of our systems. I still follow my passion and tinker around in the lab. So this product choice has a direct impact on me and the use of my lab time.

It's the little things that do the trick … I mean the “click”

(read to the end and learn about the “click” 😊)

Of all the components of an HPLC system, capillaries and fittings are relatively small and inexpensive parts. Every HPLC user will learn sooner or later that this does not mean they are less important.

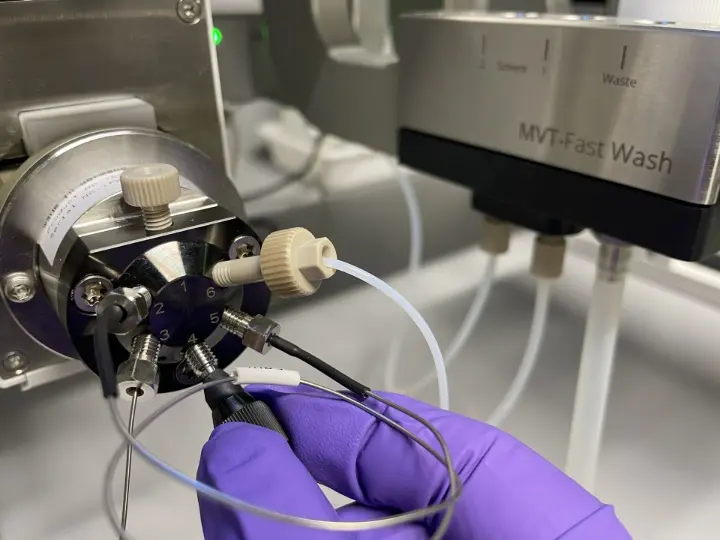

Connecting a (U)HPLC system can be difficult at some poorly accessible locations, Photo by Author

Back in the 1980s, long before the first UHPLC applications, John Dolan wrote about the correct use of chromatographic fittings to minimize dead volume. [1] Now that we have UHPLC technology with small columns and no tolerance for dead volume, this is still a hot topic.

Fun fact: Contrary to what many people think, in my experience the HPLC column is not the most common cause of problems in HPLC and UHPLC. It's the connections!

Let's take a journey through capillary technology over the years

If you also started in HPLC more than a few years ago, you may remember the days when everyone used standard, rigid 1/16" stainless steel capillaries whenever PEEK tubing was not an option. This meant that you had to find a piece of a 3 m capillary somewhere, typically in a drawer. Then you had to cut it to the desired length with a special capillary cutter, making sure you had a smooth cut surface and hoping that whoever made the last cut had done it well and not squashed the inner diameter.

The next step was to trim the capillaries with a capillary grater and bend them as required, perhaps with a bending tool. In the end you had to make the connection with the appropriate fitting and ferrule, being careful not to drop the ferrule as it would be gone forever.

Standard 1/16” Capillary and needed tools and the drawer we all know pretty well, Photos by Author

And don't fall into the trap of using a pre-assembled capillary that you also found in the drawer where the fittings are already fixed. If you are lucky, all you will do is create some unwanted dead volume in your system, leading to a loss of performance and the creation of ugly and broad peak shapes. It can take the whole lab team a while to identify, locate and fix the problem. If you are not so lucky, you can destroy a thread or a receiving port while trying to fix the miraculous leak with more force. The reason for all the trouble lies in the very different port geometries and was also described by John Dolan in the 1980s [1] and updated by Dwight R. Stoll in 2018 [2], because the issue is still relevant.

![]()

During this time, I probably spent half a day connecting an HPLC system.

If you were lucky, you skipped this ancient era of HPLC and started with pre-cut 1/16" or even flexible capillaries. It was amazing how much work, time and sanity we saved with this admittedly more expensive solution. You just chose the right length and installed it. There was no need to think about shape or bending because a flexible capillary just adapts. There was still the tiny problem of the "gone forever" ferrules on the lab floor, but overall, the installation was so much more convenient. Unfortunately, these capillaries are still one-time use items as only the capillary has been upgraded, not the fitting and connection system. This means that installation on another port is not recommended. If you have made a bad connection by not pushing the capillary into the port with enough force when screwing on the fitting, you still have to put it in your drawer forever and try again. My drawer told a sad story of low sustainability.

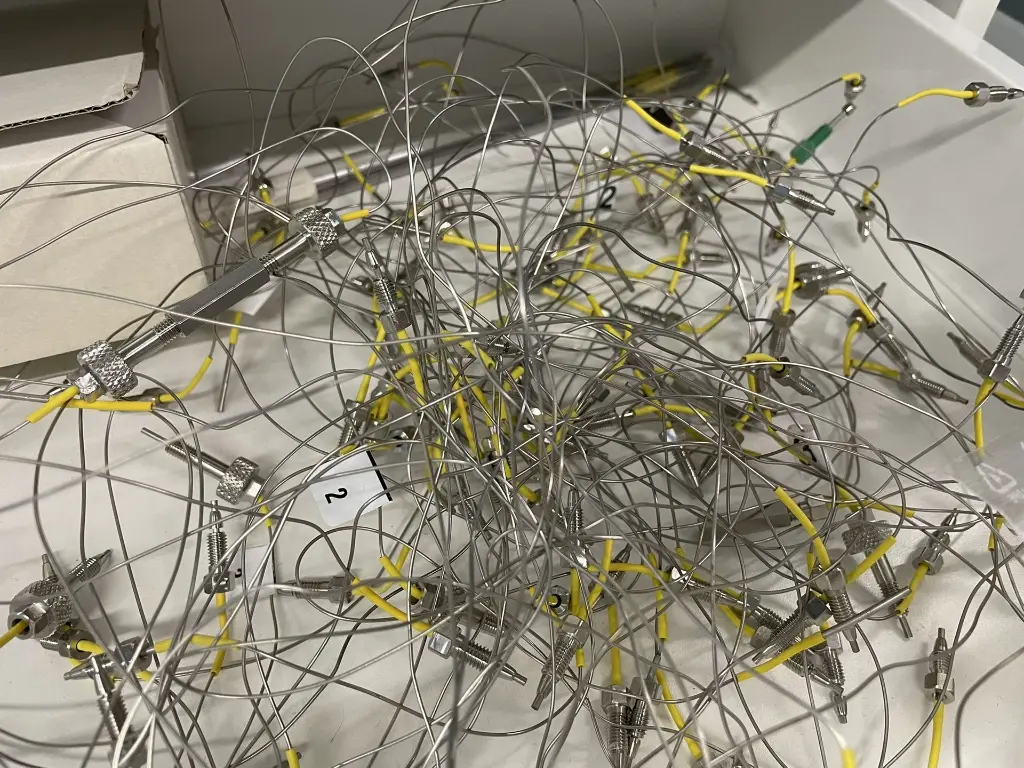

A typical capillary drawer. It was tricky to open and close it sometimes. Photo by Author

![]()

In that time, I probably still had a few more hours of work before I had a system in place.

The real revolution came a few years later when a completely different type of capillary and fitting was introduced to us, the end users, who had been desperately waiting for it. The manufacturers claimed that with these fittings all the problems would disappear.

The new fittings come pre-installed on each capillary, automatically adjust to different port depths and do not rely on ferrules. They seal at the bottom of the port without the need for complex techniques, significantly reducing the torque required. These capillaries can be connected and disconnected more than 100 times without the need for any tools as they are 100 % finger- tight.

The little things that do the “click”. Photo by Author

Do you know what that means? No more ferrules on the lab floor. Sounds too good to be true? The connection system I use now has even more to offer:

A patented torque limiting mechanism eliminates the risk of under- or over-tightening. This unique feature provides a haptic 'click' feedback when the optimum torque is reached, ensuring a perfect connection every time.

![]()

Today, it takes me less than 15 minutes to set up a complete HPLC or UHPLC system perfectly, also thanks to pre-defined start-up kits.

This is the end of the road for today, but certainly not the end of our journey. Speaking of HPLC connection systems, sustainability and ease of use have improved so much in recent years and I am very excited about where this journey could take us. Can we “click” it? Yes, we can 😊

Let´s stay connected:

If you want to learn more about KNAUER´s capillaries, fittings and (U)HPLC system start-up kits and are interested in details and numbers, I highly recommend our brand new tech note on this topic (VTN0040) and a visit to our products online https://store.knauer.net/shop/category/consumables-capillaries-44

[1] Chromatographic Fittings: Proper Use to Minimize Dead Volume, January 1, 1984 LCGC 2(1) 20-21 (1984) John W. Dolan and Vern V. Berry

[2] Fittings and Connections for Liquid Chromatography—So Many Choices!, LCGC NORTH AMERICA VOLUME 36 NUMBER 5 MAY 2018, Dwight R. Stoll

For further information on this topic, please contact our author: m.myrach@knauer.net